Catalog excerpts

Join the MF IDEAL revolution Fast-forward your harvesting business There’s a brand-new future for harvesting. The rules of the game have changed. It’s now reshaped and re-engineered to transform the way you run your harvesting business. We listened to combine owners and operators around the world - people just like you whose livelihoods depend on bringing home the harvest - and turned their wish list into practical reality. The exciting new IDEAL combine from Massey Ferguson signals a radical new direction for harvester development. It’s a machine ahead of its time which outperforms on...

Open the catalog to page 2

Inspired by innovation The future is created by people who are excited by it. The IDEAL combine is loaded with so many ground-breaking new features. At the same time, it delivers the most efficient harvesting processing and minimal daily maintenance - all packaged into a narrow width. It is an absolute gamechanger for Massey Ferguson customers! Eric Hansotia, AGCO Senior Vice President Global Crop Cycle and Fuse Connected Services

Open the catalog to page 4

It’s every engineer’s dream to design a machine from a clean sheet. And that was just the opportunity with the IDEAL combine. This was the chance to start over, to take a fresh look at every single aspect of a combine - every nut and bolt, every belt and chain and ask the question: What business benefit can this bring? How can it boost efficiency, lower operating costs, increase yields and drive profitability? It was an exciting and inspirational project for all those involved. Everyone was aware that they were participating in a turning point for harvester development. Multi-national teams...

Open the catalog to page 5

Seeds of business growth * Based on comparative data shown on competitive brand websites as of 8 August 2017. It’s a satisfying moment when you look out onto ripened crop and know that you are ready to go with the harvest. Then it’s all down to you and your combine to turn all those months of work into a profitable income. The 451-647hp MF IDEAL combines are designed for large-scale arable operations and contractors. Fully connected and with unique new features, these combines excel on all fronts, offering superb grain and straw quality, massive output, super-fast operation, outstanding...

Open the catalog to page 6

Build quality you can trust The IDEAL from Massey Ferguson combines are precision-manufactured at AGCO’s European Harvesting Centre of Excellence in Breganze, Italy. With a highly-experienced workforce dedicated exclusively to combine production, meticulous care and attention goes into the building of every machine at this modern, efficient facility. Ensuring reliability and durability in the field is the number one priority. The MF IDEAL machines are built for endurance and intense work output. Importantly, all crucial components for the combine are made in-house, further enhancing...

Open the catalog to page 8

Look forward to the harvest with confidence

Open the catalog to page 10

The MF IDEAL is the most innovative combine we have ever produced. Everything about the machine is new - new design, new engineering, new features, new styling, and a stunning new graphite livery. Imprinted with the classic Massey Ferguson signature of ease-of-use, simplicity and dependability, it all adds up to one amazing combine harvester. This is a cost-effective, sustainable business solution that will help make best use of your resources and inputs – from the land you cultivate to your seed, fertiliser and fuel. We invite you to take a good look, arrange a demonstration, assess the...

Open the catalog to page 11

Solving your individual business needs Hundreds of farmers and contractors contributed to our ‘Voice of the Customer’ survey, setting out their expectations and requirements. Our MF IDEAL design engineers responded to their wish list with key new developments in all critical areas to create the very best harvesting experience. Reliability | Durability | Fuel efficiency | Grain quality | Ease of use | Working on slopes | Residue management Soil compaction | Cab comfort/visibility | Data management | Cost of ownership * Based on comparative data shown on competitive brand websites as of 8...

Open the catalog to page 12

DRIVING FUEL EFFICIENCY We run a large-scale operation, so fuel efficiency is one of our biggest priorities.

Open the catalog to page 13

I need the best quality grain sample from the combine for my customers. Superb grain and straw quality The MF IDEAL’s low compression and extra-long rotors, which are gentle on straw, avoid contamination of the sample. The Dual Helix (double rotors) system on the MF IDEAL 8 and MF IDEAL 9 boasts the largest main threshing concave area on the market – a massive 1.66m2 – 25% bigger* than any other combine in the industry. This assures low grain losses at high output and delivers more grain in the tank per hectare. During threshing, low pressure on the straw mat damages less grain, producing a...

Open the catalog to page 14

* Based on comparative data shown on competitive brand websites as of 8 August 2017.

Open the catalog to page 15

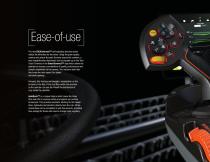

The new IDEALharvest™ self-adjusting function option makes life effortless for the driver. Using the grain-quality camera and unique Acoustic Sensors around the combine, a very straightforward dashboard can be brought up on the Tech Touch Terminal or the SmartConnect™ App which allows the operator to choose a combination of quality, performance and sample cleanliness for his harvest. The machine itself then fine-tunes the rotor speed, fan speed and sieve opening. Uniquely, this function can provide a visualisation on the terminal or the App of the crop flow within the machine so the...

Open the catalog to page 16

As a contractor, we employ several drivers in high season so it’s crucial for the combines to be easy to operate.

Open the catalog to page 17

Working on slopes The MF IDEAL combines are fitted with the unique IDEALbalance™ grain-pan system. With no extra moving parts, the combination of the two specially-shaped under-rotor pans is insensitive to slopes up to 15% and places the grain mix in exactly the right position for the separation pan, sieve box and fan to produce a clean sample at high output. For those that have a higher proportion of slopes, a ParaLevel version of each model is available where the machine uses a special axle arrangement to keep the whole machine level up to 14%. These models are equipped with the Streamer...

Open the catalog to page 18All MASSEY FERGUSON catalogs and technical brochures

-

MF 5M

17 Pages

-

MF 5S

27 Pages

-

MF 1842S

3 Pages

-

MF 1500 & MF 1700 M

15 Pages

-

MF 3 SPECIALITY SERIES

9 Pages

-

MF 7S

27 Pages

-

MF 3700

24 Pages

-

MF 5700 S

48 Pages

-

MF 4700, MF 5700 & MF 6700

38 Pages

-

MF 6700 S

56 Pages

-

MF7100

12 Pages

-

2018 MF Hay & Forage

8 Pages

-

Global Series Brochure

38 Pages

-

MF 8700 S

8 Pages

-

New MF 7700 S Brochure

8 Pages

-

MF 290 Xtra

2 Pages

-

MF 275 Xtra

2 Pages

-

MF 268 Xtra

2 Pages

-

MF 240 Xtra

2 Pages

-

MF Rakes

16 Pages

-

MF DM & M Series

20 Pages

-

MF Tedders

12 Pages

-

MF FL

38 Pages

-

MF TH

28 Pages

-

MF Activa 7344

12 Pages

-

MF Activa S

32 Pages

-

MF Beta

36 Pages

-

MF Centora & Delta

56 Pages

-

MF 2200

36 Pages

-

MF 6600

52 Pages

-

MF 5700 SL

48 Pages

-

MF Tractor 5600

48 Pages

-

MF 4700

26 Pages

-

MF 3600 A

32 Pages

-

MF 3600 V/S/F/GE

36 Pages

-

MF DM Series

16 Pages

-

MF 1840

20 Pages

-

MF 1500/1700

20 Pages

Archived catalogs

-

2016 MF Hay & Forage

8 Pages

-

MF ACTIVA 7340

8 Pages