Catalog excerpts

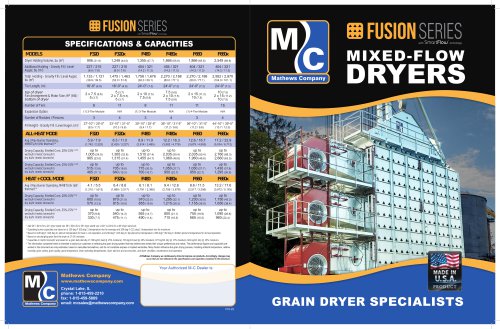

FUSION SERIES with FUSION SERIES SPECIFICATIONS & CAPACITIES MODELS Dryer Holding Volume, bu (m ) Additional Holding - Gravity Fill / Level Auger, bu (m3) top of dryer Fan Arrangement & Motor Size, HP (kW) bottom of dryer ALL-HEAT MODE Avg / Max Burner Operating, MMBTU/hr (kW thermal)2,6 Drying Capacity, Shelled Corn, 20%-15%3,4,5,6 Drying Capacity, Shelled Corn, 25%-15%3,4,5,6 Total Holding - Gravity Fill / Level Auger, bu (m3) Number of Tiers Expansion Option Number of Modules / Plenums Fill Height - Gravity Fill / Level Auger, (m)1 wet bu/hr (metric tonnes/hr) dry bu/hr (metric tonnes/hr) wet bu/hr (metric tonnes/hr) dry bu/hr (metric tonnes/hr) HEAT + COOL MODE Avg / Max Burner Operating, MMBTU/hr (kW thermal)2,6 Drying Capacity, Shelled Corn, 20%-15%3,5,6 Drying Capacity, Shelled Corn, 25%-15%3,5,6 wet bu/hr (metric tonnes/hr) dry bu/hr (metric tonnes/hr) wet bu/hr (metric tonnes/hr) dry bu/hr (metric tonnes/hr) Add 24" (.61m) for a 24" dryer stand set, 36" (.92m) for a 36" dryer stand set, or 48" (1.22m) for a 48" dryer stand set. Operating burner capacities are based on a 150 deg F (83 deg C) temperature rise for average and 200 deg F (111 deg C) temperature rise for maximum. 3 Based on 240 deg F (116 deg C) plenum temperature for heat + cool operation, and 240 deg F (116 deg C) top plenum(s) temperature / 180 deg F (82 deg C) bottom plenum temperature for all-heat operation. 4 Based on discharging grain from the dryer at 17.0% moisture. 5 Capacities in metric tonnes/hr are based on a grain bulk density of: 749 kg/m3 (wet @ 25% moisture), 703 kg/m3 (wet @ 20% moisture), 677 kg/m3 (dry @ 17% moisture), 661 kg/m3 (dry @ 15% moisture). 6 T he information contained herein is intended to assist our customers in selecting the grain drying system that they believe best meets their unique preferences and needs. The performance figures and capacities presented in this document are only estimates, based on calculated simulations, and do not constitute express or implied warranties. Many factors influence the grain drying process, including ambient temperature, relative humidity, grain variety, grain quality, grain temperature, dryer operating temperatures, dryer add-ons and accessories, and dryer condition, maintenance and operation. 1 2 At Mathews Company, we continuously strive to improve our products. Accordingly, changes may occur that are not reflected in the specifications and capacities contained in this brochure. Your Authorized M-C Dealer is: Mathews Company www.mathewscompany.com Crystal Lake, IL phone: 1-815-459-2210 fax: 1-815-459-5889 email: mcsales@mathewscompany.com V10-22 GRAIN DRYER SPECIALISTS

Open the catalog to page 1

FUSION SERIES with Future Growth is possible with an easy-to-expand design allowing for an additional plenum to be added (on select models). Pinnacle 20|20, the standard dryer control system on all M-C dryers, features an intuitive, 10” (25.4cm) HD touchscreen for ultimate control, customization and usability. AccuDry™ Moisture-Based Control is an available option featuring DryerMaster™ technology which measures incoming and discharged grain moisture to control the discharge rate of the dryer, ensuring precise and uniform grain moisture. 10" U-Trough Unload Auger with ultra-convenient quick...

Open the catalog to page 2All Mathews Company catalogs and technical brochures

-

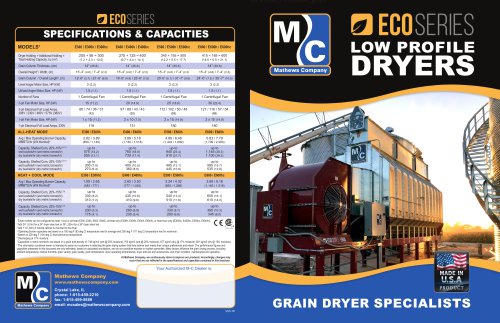

ECOSERIES

2 Pages

-

DELTA SERIES

2 Pages

-

DRYER CONTROL AND MONITORING

2 Pages

-

Modular Tower Brochure

2 Pages

-

ECO_Series_Brochure

2 Pages

-

Shredders

2 Pages

-

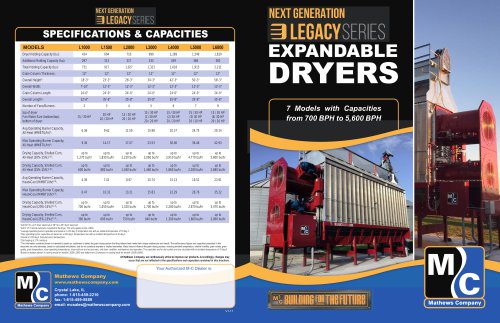

Legacy

2 Pages

-

ECO_Brochure

2 Pages

-

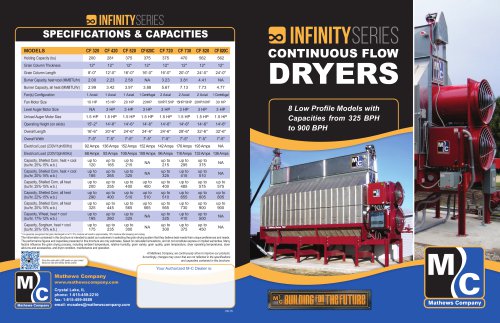

Infinity

2 Pages

-

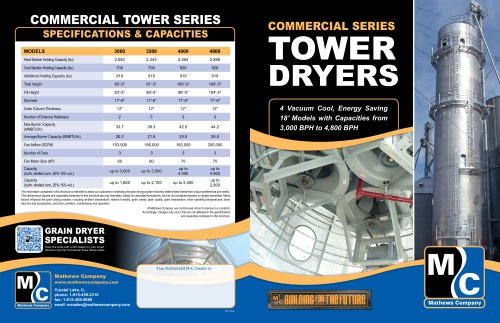

Commercial Tower

2 Pages

-

Modular Tower

2 Pages