Catalog excerpts

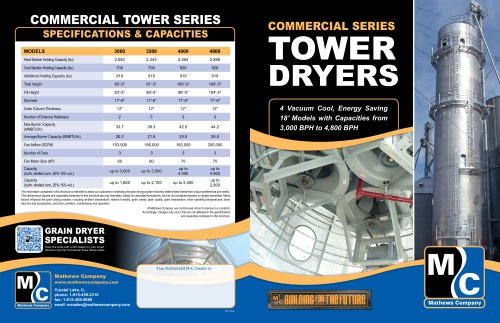

MODELS Heat Section HoldingCapacity, bu (m3) Cool Section Holding Capacity, bu (m3) Wet Hopper Holding Capacity, bu (m3) Total Holding Capacity, bu (m3) Total Height, (m)1 Fill Height, (m)1 Diameter, (m) Grain Column Thickness, (cm) Number of External Walkways Grain Exchanger Average Operating Burner Capacity, MMBTU/hr (kW thermal)2 Max Operating Burner Capacity, MMBTU/hr (kW thermal)3 Max Nameplate Burner Capacity, MMBTU/hr (kW thermal) Electrical Load, Amps 230V / 460V (380V) Fan Airflow, CFM (m3/hr) Number of Fans Fan Motor Size, HP (kW) Capacity, Shelled Corn, 20%-15%4 wet bushels/hr (wet metric tonnes/hr)5 dry bushels/hr (dry metric tonnes/hr)5 Capacity, Shelled Corn, 25%-15%4 wet bushels/hr (wet metric tonnes/hr)5 dry bushels/hr (dry metric tonnes/hr)5 Your Authorized M-C Dealer is: 1Grain exchanger option adds 3'-0" (.91m) to models 10950 - 101375 and 4'-0" (1.22m) to models 12-20-100 - 12-28-150. 2Average burner Capacities based on 150 deg F (83 deg C) temperature rise and 20% reclamation efficiency. 3Max burner Capacities based on 200 deg F (111 deg C) temperature rise and 20% reclamation efficiency. 4The information contained in this brochure is intended to assist our customers in selecting the grain drying system that they believe best meets their unique preferences and needs. The performance figures and capacities presented in this brochure are only estimates, based on calculated simulations, and do not constitute express or implied warranties. Many factors influence the grain drying process, including ambient temperature, relative humidity, grain variety, grain quality, grain temperature, dryer operating temperatures, dryer add-ons and accessories, and dryer condition, maintenance and operation. Capacities in metric tonnes/hr are based on a grain bulk density of: 749 kg/m3 (wet @ 25% moisture), 703 kg/m3 (wet @ 20% moisture), 661 kg/m3 (dry @ 15% moisture). At Mathews Company, we continuously strive to improve our products. Accordingly changes may occur that are not reflected in the specifications and capacities contained in this brochure. 3 MODULAR TOWER SERIES SPECIFICATIONS & CAPACITIES 10950 101160 101375 12-20-100 12-24-125 12-28-150 Optional Optional Optional Optional Optional 3 MODULAR TOWER SERIES TOWER DRYERS

Open the catalog to page 1

Vacuum Cool Energy Savings Vacuum cooling is key to the popularity and success of M-C Tower Series dryers. Reclaiming heated air from cooling grain results in less fuel usage and significant dollar savings. After blending the ambient air drawn from outside, the pre-heated air is returned to the blower, lowering energy consumption and producing maximum efficiency. Experience the Ease of Dual Touch Screens with Pinnacle 20|20 • PLC-Based Dryer Control System • Dual 10" HD Touchscreens • Easy User Interface • 24 VDC Control Safety Circuit M-C Tower Series dryers give maximum capacity while...

Open the catalog to page 2All Mathews Company catalogs and technical brochures

-

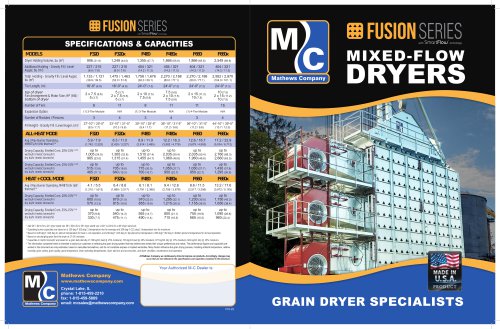

MIXED-FLOW DRYERS

2 Pages

-

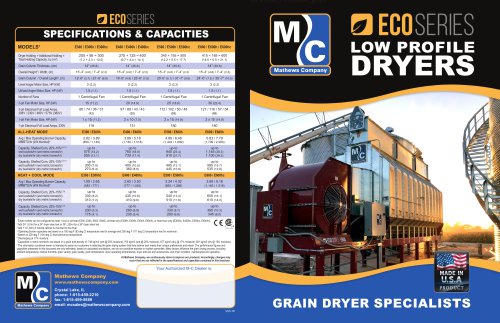

ECOSERIES

2 Pages

-

DELTA SERIES

2 Pages

-

DRYER CONTROL AND MONITORING

2 Pages

-

ECO_Series_Brochure

2 Pages

-

Shredders

2 Pages

-

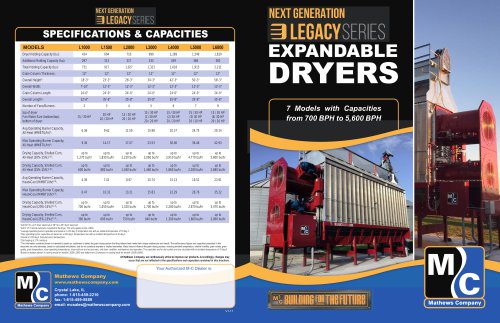

Legacy

2 Pages

-

ECO_Brochure

2 Pages

-

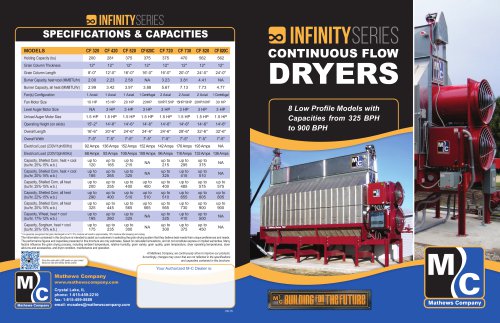

Infinity

2 Pages

-

Commercial Tower

2 Pages

-

Modular Tower

2 Pages