Catalog excerpts

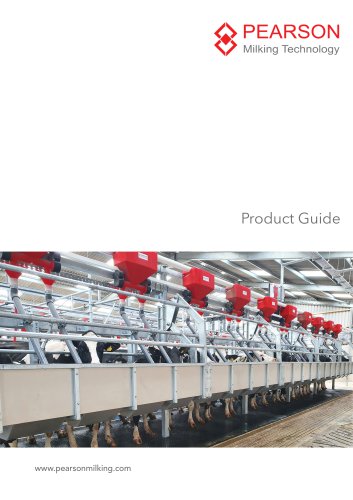

PEARSON <3> Milking Technology

Open the catalog to page 1

Pearson Milking Technology Athy, Co.Kildare Ireland Tel: 00353 59 8631842 E: info@pearsonmilking.com

Open the catalog to page 2

Welcome... Pearson Milking Technology Over the decades, since its formation, Pearson has been helping the dairy farmer pursue greater and more efficient milk yields. The practical use of modern materials and state of the art electronic systems have lead to a durable and innovative product range designed and manufactured in Ireland and sold throughout the world. These long years of experience work to the advantage of the dairy farmer, as the high standard of quality and reliability in Pearson Milking Technology, keeps running costs to a minimum and performance to a maximum. Whether you want...

Open the catalog to page 3

Contents... Manufacturing. . . . . . . . . . . . . . . . . . . . . . Planning your dairy. . . . . . . . . . . . . . . . . . Testimonials. . . . . . . . . . . . . . . . . . . . . . . . . Page 12 Milking Systems. . . . . . . . . . . . . . . . . . . . . Rotary Parlour. . . . . . . . . . . . . . . . . . Herringbone Parlour. . . . . . . . . . . . Stallwork Systems . . . . . . . . . . . . . . . . . . . Milking Equpiment. . . . . . . . . . . . . . . . . . Milk Delivery Options. . . . . . . . . . . . . . . . Page 58 Parlour Automation. . . . . . . . . . . . . . . . . . Milk Recording. . . . . . . ....

Open the catalog to page 6

8 | Fresh Thinking... Better Milking.

Open the catalog to page 8

Pearson Products Research & Design Over the past 70 years, Pearsons have introduced innovative ideas into the dairy industry, knowing some of the best ideas come from from people who use their equipment everyday. We are always seeking ways to improve what we deliver and develop better solutions for the future. We are passionate about creating breakthrough technology and high performance products, easily operated that provide dairy farmers with optimum efficiency and cow comfort! With strong focus on research and development within our company values we strive to create exceptional products...

Open the catalog to page 9

What system suitsmy cows Type of dairy farming Depending on the type of dairy you are running can influence the machine and equipment being purchased. Herd size When planning the parlour size. Taking into account the future size of the dairy is very important. Cow flow Having smooth stress free cow flow to the collecting yard , through the parlour and out of the dairy through the selection system. Milking time Time in the parlour for your cows should be kept to a minimum. Keeping in mind your milking routine, consider a goal time to have your cows milked. Check List • Trades People -...

Open the catalog to page 10

Express Fit Installation Pearson herringbone parlours can be delivered as an Express-Fit package. The relevant stallwork is assembled and all equipment ordered on the parlour is fitted, wired and tested by experienced technicians in the Pearson factory. The parlour is then delivered by an articulated truck to the farm where it is installed into the milking shed within hours. Installation technicians then proceed to install other features of the machine depending on the items purchased. Parlours may be installed into new sheds in a matter of days or if the new parlour is being placed where...

Open the catalog to page 11

John Phelan Name: John Phelan Herd Size: 165 Cows Parlour: Rapid Exit Technology: ProFarm,i100,Forward Motion Herd Management: SmartTag,Animal Selection “I wanted a one-man operation” “With the heat detection system I definitly have less repeats than last year” “I dont mind coming to milk anymore, I dont have to leave the pit. It is a lot less stressfull on the cow and operator”

Open the catalog to page 13

Brownstown Estate Name: Shane Corbaly Herd Size: 330 Cows Parlour: 50 Point Rotary Technology: Global ProFarm,Milk Meter Herd Management: Crowd Gate,Animal Selection “An excellent addition to the farm” “Very happy with the milk meters. Its a game changer having access to that level of information on individual yeilds” “Drafting unit has made life a lot easier with jobs like hoof pairing, AI and drying off” Fresh Thinking... Better M

Open the catalog to page 14

Bradford Down Farm Name: James Dovey Herd Size: 165 Cows Parlour: Swingover Technology: ProFarm,i100,Milk Seperation Line Herd Management: MRS,Animal Selection “We prefered the Pearson parlour over other makes” “We liked dealing with the manufacturer, rather than just a sales rep” “The parlour size, layout, its all brilliant. I would really recommend Pearsons”

Open the catalog to page 15

Fresh Thinking... Better Milking...

Open the catalog to page 16

Product Guide

Open the catalog to page 17

Fresh Thinking... Better Milking...

Open the catalog to page 18

Rotary Milking Parlours Comfort for the Cow, and Operator To handle milking on large herd dairies, rotary milking parlours are an efficient use of space, labour and time. To create the most comfortable milking experience for the cow while on the rotary platform, each cow has their own bail area and feed trough, thus preventing bullying and creating a more relaxed environment for the cow. With almost constant cluster application and less operator movement, the rotary parlour proves to be one of the fastest ways to milk cows. Incorporating Milk Metering with Pearson’s ProFarm Management...

Open the catalog to page 19

Pearson Rotary Decks The perfect combination of cow comfort, operator ease and durable construction. Extra Efficiency • Speed up milking time • Quick entry & exit • Less Labour Fresh Thinking... Better Milking... Durable Design • Robust construction • Reliable operation • Low maintenance costs Excellent Experience • Added cow comfort • Operator friendly • Easier

Open the catalog to page 20

Features of the Orbitor Rotary Deck Industrial Roller System A double I beam nylon roller system, both heavy gauge 180 x 75 I beams are fully galvanised, the bottom I beam is mounted on galvanised feet (one per unit) to give max strength & support. The nylon rollers are placed on the bottom I beam and connected with a carriage system. The top I beam is then positioned on the nylon rollers. This will be the moving beam. There are no bearings incorporated in any of the nylon rollers, giving one of the most industrial, long lasting roller systems on the market. Deck Design The concrete deck is...

Open the catalog to page 21