Catalog excerpts

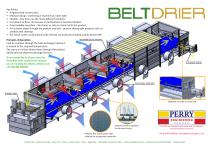

Key Points: • All galvanised construction. • Modular design - Extend your machine at a later date. • Flexible - One drier can dry many different products. • Consistant air flow - No louvres or perforations to become blocked. • Good reliable operation – No chains or slats in contact with the product. • Air is drawn down through the product and belt – good at drying light products such as sawdust and shavings. • PLC touch screen control panel with internet connectivity including mobile phone APP. Principle of Operation Cold air is drawn through the heat exchangers where it is heated to the required temperature. The warm air is then drawn down through the product bed & belt and dispersed through the fans. If you would like to discuss how the Perry Belt Drier could be the solution you are looking for please contact us on +44 (0)1404 890300 Product Outlet Low power axial fans Product inlet Optional air knife to clean belt Optional product agitators to aid even drying Polymer fine mesh woven belt, suitable for drying most materials The UK’s most experienced manufacturer of materials drying & handling equipment Wood chip - Wood shavings - Saw dust - Straw - Paper pulp - Grass - Digestate - Shredded recycled matter - Solid shredded waste - Granular & shredded plast

Open the catalog to page 1All Perry Engineering Services Ltd. catalogs and technical brochures

-

BELT DRIER

20 Pages

-

COBRA

2 Pages

-

SARA

2 Pages

-

Grain & Bulk Handling Equipment

40 Pages

-

Grain Handling

32 Pages

-

TPLG Brochures Full Range email

12 Pages