Catalog excerpts

The UK’s most experienced manufacturer of materials handling & drying equipment.

Open the catalog to page 1

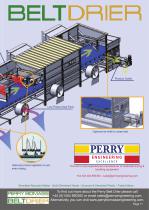

Contents General Design Heat Source Options Belt Information PLC Control Panel Remote Desktop Operation Control Panel App Options Infeed Options Belt Cleaning Hot Air Recirculation Fire Detection & Suppression Stacked Driers Insulated Enclosure Example Driers Wood Examples Grass Examples Waste Examples View of the Exhaust Plenum Fine mesh drying belt. All galvanized construction - stainless steel as an option. Multiple heat sources available including biomass, steam, oil, kerosene or gas. PLC touch screen panel with internet connectivity. Levelling device. Modular construction. Rotary brush...

Open the catalog to page 2

The Perry Belt Drier is ideally suited to drying almost any nonflowing product. Popular applications have included biomass, anaerobic digestate, grass & seeds. The Perry Belt Drier is ideally suited for these materials: Wood chip Wood shavings Wood pellets Other feed pellets Saw dust Biomass straw Miscanthus and bagasse Herbs Combinable crops Beans and soya beans Shredded recycled matter Sewerage sludge & Digestate Flaked maize Nuts Fruit and fruit slices Compost Cotton rejects Extruded pet foods Finely ground wet chips Grass Grass seed Orange peel Pulp granulates Solid shredded waste...

Open the catalog to page 3

General Design Modular galvanised steel construction available in 1.5m, 2.2m and 3m widths. The drier can be increased in length in 1m increments from 8.5m to 65m (including drive and tail). The overall height of the drier is dependent on the heat source chosen. • There is a rotary brush to clean the belt as standard - for usual biomass and granular products this is satisfactory. Every piece of the belt is cleaned once per revolution automatically. • Automatic control as standard is by measuring air temperature on the same principle as the grain drier. The way this works is to measure the...

Open the catalog to page 4

General Design • The Perry Belt Drier has an automatic belt tracking device which works using a sensor at the side of the belt, which senses if the belt travels to one side. If the sensor is touched an electric actuator changes the angle of the tracking roller which sends the belt across to the opposite side. • The Perry belt drier does not have chains or slats, keeping it very clean. In driers with slats and chains, products such as grass or herbs will leave residue. This will decompose and the bacterial count inside the drier will increase. In the Perry belt drier there is less chance of...

Open the catalog to page 5

Heat Source Options Heat Exchangers • Heat exchangers are commonly used for applications where a biomass heat source is available such as woodchip boilers to produce hot water, or if there is a steam heat source available. The drier can be tailored to accept existing heat exchangers if required. If a separate heat source is required a direct fired furnace with diesel, kerosene, LPG or natural gas burner can be used. Alternatively a heat exchanger with the same burner can be used for indirect heating if required. Belt Information Fitted with a universal belt, the Perry belt drier is suitable...

Open the catalog to page 6

Heat Exchangers Kerosene Burners To find out more about the Perry Belt Drier please call +44 (0)1404 890300 or email sales@perryengineering.com. Alternatively you can visit www.perrybiomassengineering.com. Page 7

Open the catalog to page 7

PLC Control Panel Overview • 12” touch screen. • Simple operation. • Plain language status alerts. • Designed and programmed in house. • Data logging of all readouts and alarms and drier status. • Moisture contents can be entered can be entered during the day. • Export all recorded drier conditions and moisture contents to a spreadsheet and automatically create daily record sheets. • Fuel use calculator included for diesel applications. Internet Connectivity Connect the Perry PLC panel to the internet to: • Allow status reports to be sent to selected mobile numbers and email addresses. •...

Open the catalog to page 8

Full control of your drier from anywhere with a WiFi or 3G/4G connection! Free app available from both Apple App Store and Google Play Store. • Control the Perry PLC drier or plant panel from your phone. • Two settings - either view or control the panel. • Full zoom compatibility making the buttons and screen easier to read. • Static IP and passwords mean the connection is secure. • Multiple applications can be installed on different devices. • Multiple panels can be installed on each application. The app allows users more flexibility when operating their driers; you can now operate the...

Open the catalog to page 9

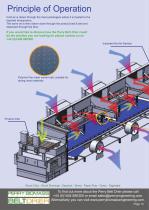

Principle of Operation Cold air is drawn through the heat exchangers where it is heated to the required temperature. The warm air is then drawn down through the product bed & belt and dispersed through the fans. If you would like to discuss how the Perry Belt Drier could be the solution you are looking for please contact us on +44 (0)1404 890300. Insulated Hot Air Section Polymer fine mesh woven belt, suitable for drying most materials. Product Inlet Wood Chip - Wood Shavings - Sawdust - Straw - Paper Pulp - Grass - Digestate To find out more about the Perry Belt Drier please call +44...

Open the catalog to page 10

Product Outlet Low Power Axial Fans Optional air knife to clean belt. Optional product agitators to aid even drying. The UK’s most experienced manufacturer of materials drying & handling equipment. +44 (0)1404 890300 - sales@perryengineering.com Shredded Recycled Matter - Solid Shredded Waste - Granular & Shredded Plastic - Flaked Maize To find out more about the Perry Belt Drier please call +44 (0)1404 890300 or email sales@perryengineering.com. Alternatively you can visit www.perrybiomassengineering.com. Page 11

Open the catalog to page 11

Options Infeed Options • Screw feeder - a feeding hopper that can be used as a buffer hopper to help feed the product evenly over the belt. This feeding hopper will have a number of screw feeders dependant on the width of drier chosen. The hopper can be fed via dump loading, elevators, conveyors or screw conveyors. • Belt feeder - this can be used singularly or in a row of multiple feeders. The belt feeder ensures a level product bed going into the drier & acts as a buffer hopper. • 2m buffer hopper - a 2m tall buffer hopper can be added to screw feeders to ensure the drier is fed at a...

Open the catalog to page 12All Perry Engineering Services Ltd. catalogs and technical brochures

-

COBRA

2 Pages

-

SARA

2 Pages

-

Grain & Bulk Handling Equipment

40 Pages

-

Grain Handling

32 Pages

-

TPLG Brochures Full Range email

12 Pages

-

Belt drier Principle of Op_0

1 Pages