Catalog excerpts

The PETKUS Indented Cylinder Separators ZA are used for the sorting of seed, grain, fine and vegetable seeds, corn and similar agricultural, grained and free flowing granular products. The material is sorted according to its length. The indented cylinders are available in different sizes and performance categories. Construction: The separator is equipped with an indented cylinder for short grain and an Indented Cylinder for long grain Separation. The trough with a transport screw is inside the indented cylinder. Each indented cylinder is driven with a gear motor. Short Grain Separation – separating short particles: The short particles Standard Equipment: settle in the indents. The short particles are transported to the top and Bolted frame made of sheet steel discharged into the discharge trough by turning the indented cylinder. Indented cylinder for long grain Long Grain Separation – separating long particles: The product settles Indented cylinder for short grain in the indents. The product is transported to the top and discharged into Discharge troughs with transport screw the discharge trough by turning the indented cylinder. The long particles Drive units with electric motor remain in the indented cylinder and are discharged. Aspiration connection Advantages: Gentle processing of the product High standard of separating quality Indented cylinders completely covered Simple and quick changing of the cylinder casings Individual drive unit for each indented cylinder Operation smooth and free of vibration Options: Cylinder casings available with various cell sizes Indent cells The Indented Cylinder Separator machines are equipped with an indented cylinder for long grain separation and a cylinder for short grain separation. The product is moved from the inlet hopper through the turning indented cylinder. Pocket-shaped cells are stamped in the segments of the indented cylinder. The grain settles in these sells depending on the size of the cells. By rotating the indented cylinder the settled grain is transported to the top and falls into the trough at a height dependant on its center of gravity. A transport auger within the trough transports the separated grain to the product outlet. The particles of the product not picked up by the cells of the indented cylinder or which have fallen down below the discharge trough because of their length remain in the indented cylinder and are transported to the corresponding product outlet. The discharges are guided outwards separately. Samples for the two discharges can be taken at the sampling points. PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone:+49 36921-98

Open the catalog to page 1

*Wheat with 3% impurities Technical alteration reserved. PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone:+49 36921-98 0 | E-mail: info@pe

Open the catalog to page 2All PETKUS Technologie GmbH catalogs and technical brochures

-

Optical sorter OS T roeber

3 Pages

-

Pre-Cleaner V 12 / V 15

2 Pages

-

PETKUS K-Series

3 Pages

-

Indented Cylinder ZK / ZL

2 Pages

-

Continuous Flow Dryer DW

2 Pages

-

Gravity Table G f-series

2 Pages

-

Gravity Table Type G 20

2 Pages

-

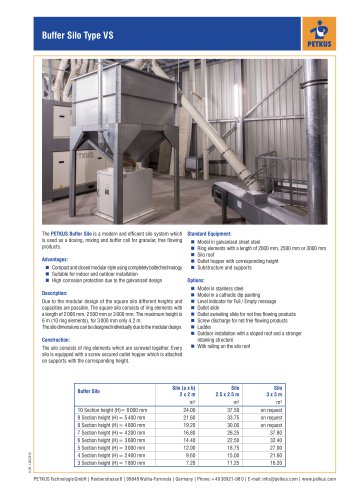

Buffer Silo Type VS

2 Pages

-

Smooth Wall Silo GWS

2 Pages

-

Profile Wall Silo Type PWS

2 Pages

-

Bucket Elevator Type BE 100

2 Pages

-

Continuous Flow Dryer DWU

2 Pages

-

SE 03

2 Pages

-

Dust Extraction System

2 Pages

-

Storage and Buffer Silo

2 Pages

-

Smooth Wall Silo

2 Pages

-

Wall Silo PWS

2 Pages

-

MultiCoater CM 100

2 Pages

-

Chemical Mixer Type 200

1 Pages

-

Continuous Flow Dryer DD

2 Pages

-

A-cleaner

2 Pages