Catalog excerpts

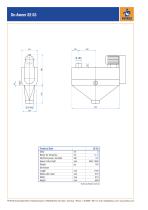

De-Awner SE 03 The purpose of the PETKUS De-Awner SE 03 is the processing of brewing barley, cereals and forage seed. The De-Awner is used specifically for: ■ De-awning barley ■ De-husking wheat ■ Clipping oats ■ Separating seed clusters ■ Polishing seed Advantages: ■ Robust and wear-resistant construction ■ Adjustable processing intensity Description: The product is transported into the machine through the inlet. The agitator shaft with the pin beaters removes awns, clippings, and beards from the product. The product flows out of the De-Awner through the adjustable bottom slide of the outlet. The processing intensity can be adjusted by the speed (two stages) and the adjustable bottom slide. Construction: The De-Awner is equipped with a sheet steel housing with the agitator shaft and the pin beaters. The inlet is on the top of the machine. The outlet with the adjustable slide is under the machine. The machine is operated by a V-belt system with an electric motor driving the agitator shaft. Standard Equipment: ■ Bolted frame made of sheet steel ■ Agitator shaft with round pin beaters ■ Drive unit with electric motor Options: ■ Lining of the interior with indented cells PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone: + 49 36921-98 0 | E-mail: info@petkus.com| www.petkus.com

Open the catalog to page 1

Technical alteration reserved. PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone: + 49 36921-98 0 | E-mail: info@petkus.comj www.petkus.com

Open the catalog to page 2All PETKUS Technologie GmbH catalogs and technical brochures

-

Optical sorter OS T roeber

3 Pages

-

Pre-Cleaner V 12 / V 15

2 Pages

-

PETKUS K-Series

3 Pages

-

Indented Cylinder ZK / ZL

2 Pages

-

Continuous Flow Dryer DW

2 Pages

-

Gravity Table G f-series

2 Pages

-

Gravity Table Type G 20

2 Pages

-

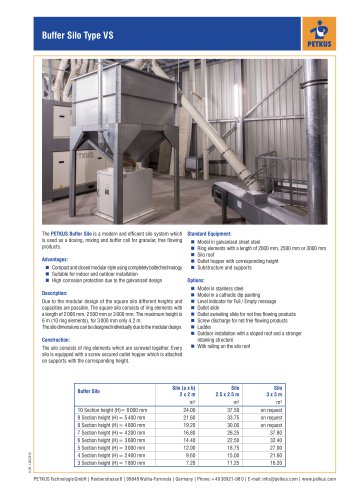

Buffer Silo Type VS

2 Pages

-

Smooth Wall Silo GWS

2 Pages

-

Profile Wall Silo Type PWS

2 Pages

-

Bucket Elevator Type BE 100

2 Pages

-

Continuous Flow Dryer DWU

2 Pages

-

Dust Extraction System

2 Pages

-

Storage and Buffer Silo

2 Pages

-

Smooth Wall Silo

2 Pages

-

Wall Silo PWS

2 Pages

-

MultiCoater CM 100

2 Pages

-

Chemical Mixer Type 200

1 Pages

-

Continuous Flow Dryer DD

2 Pages

-

Indented Cylinder ZA

2 Pages

-

A-cleaner

2 Pages