Catalog excerpts

Trough Belt Conveyor MB 300 / MB 400 The purpose of the PETKUS Trough Belt Conveyors MB 300/ MB 400 Standard Equipment: is to transport homogenous, free flowing bulky products, e.g. grain, Model in galvanized sheet steel pulses and oil seeds. Drive station with electric motor Tensioning station Advantages: Oil and grease resistant conveying belt Homogeneous and gentle transport Inlet and outlet Modular design through duct lengths of 500 mm, 1 000 mm, 2 000 mm and 3 000 mm Options: Completely closed conveyor belt Speed monitoring Description: The transport of the product is usually carried out from the tensioning station to the drive station. The product is moved from the inlet onto the trough belt and transported to the outlet on the conveying belt. The conveying belt slides on a molded channel with support rollers and is sealed on the sides. The lower run runs on support rollers. The conveying belt is driven over a driving drum by the drive motor at the drive station. The conveying belt is tensioned on the opposite side by the tensioning station. Aspiration connection for de-dusting Type Capacity (dimensioning 0.75 t/m³) Belt width The Trough Belt Conveyor consists of a drive and a tensioning station, the pits with the conveying belt as well as the inlet and the outlet. The drive is operated with a gear motor. Belt speed PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone:+49 36921-98

Open the catalog to page 1

Trough Belt Conveyor MB 300 / MB 400 Technical Alteration reserved. PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany | Phone:+49 36921-98 0 | E-mail: info@petkus.

Open the catalog to page 2All PETKUS Technologie GmbH catalogs and technical brochures

-

Optical sorter OS T roeber

3 Pages

-

Pre-Cleaner V 12 / V 15

2 Pages

-

PETKUS K-Series

3 Pages

-

Indented Cylinder ZK / ZL

2 Pages

-

Continuous Flow Dryer DW

2 Pages

-

Gravity Table G f-series

2 Pages

-

Gravity Table Type G 20

2 Pages

-

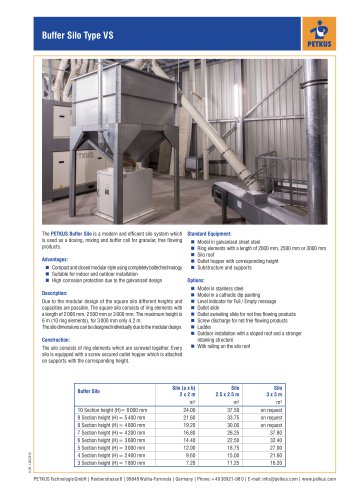

Buffer Silo Type VS

2 Pages

-

Smooth Wall Silo GWS

2 Pages

-

Profile Wall Silo Type PWS

2 Pages

-

Bucket Elevator Type BE 100

2 Pages

-

Continuous Flow Dryer DWU

2 Pages

-

SE 03

2 Pages

-

Dust Extraction System

2 Pages

-

Storage and Buffer Silo

2 Pages

-

Smooth Wall Silo

2 Pages

-

Wall Silo PWS

2 Pages

-

MultiCoater CM 100

2 Pages

-

Chemical Mixer Type 200

1 Pages

-

Continuous Flow Dryer DD

2 Pages

-

Indented Cylinder ZA

2 Pages

-

A-cleaner

2 Pages