Catalog excerpts

Universal Cleaner F 12 / P 12 justable supply flap. This flap allows for an optimal separation effect. For both cleaners a combined cleaning method via ball and scraper chain is used to clean the upper screen. The bottom screens of the P 12 are also cleaned by the ball method whereas the bottom screen of the F 12 uses brush cleaning, which regardless of the motor speed, ensures optimal screen efficiency. Construction: The PETKUS F 12 and P 12 cleaners are equipped with an inlet hopper, a pre and final air separation, with depositing chambers and discharge auger as well as two counter vibrating screen compartments. The various components of the machine (inlet hopper, discharge auger, scraper chain, etc.) are operated by drive motors. Standard Equipment: Compact, closed and bolted frame made of painted sheet steel Screen compartments, pre-aspiration and final aspiration made of galvanized sheet steel Set of screens for corresponding screening diagram Individual drive units with gear motors PETKUS F 12 and P 12 Universal Cleaners are tried and tested and used Options: Broad range of screens for all types of crops for the high quality cleaning of cereals, legumes, and above all, grass and Pin drum in-feed fine seeds. The compact air-screen cleaner can be used for pre or intensive Aspiration connection cleaning, as well as for seed cleaning. Within a specific technological process the cleaners can also be set up in series. The P 12 Cleaner is the cleaner of choice for mobile seed cleaning plants due to its compact, low vibration design. The cleaner is fitted with a standard screen set up consisting of two screen compartments and three screen layers with ball cleaning. Conversely, the F 12 features a variable screen configuration, in which the middle screen can be arranged in two different constellations. The bottom screen is cleaned by brush. Advantages: High flexibility through variable screen diagrams and extensive setting options High cleaning capacity and quality Also suitable for the grading of fine seeds Low mass imbalance due to separate screen compartments, therefore also suitable for mobile systems Highly efficient screen cleaning through ball cleaning and scraper chain Only the F 12: Bottom screens can be run in sequence or parallel Brush cleaning ensures screen efficiency independent of motor speed Seed cleaning for grain Description: The in-feed consists of a weight-loaded cylindrical roller. For poor flowing products, one can opt to use a pin drum. This in-feed guarantees a broad and uniform dispersion over the complete screen surface independent of the product and capacity. In the air-separator light dust particles are separated and then deposited into the discharge chamber and removed via a screw auger. The separation of coarse or large particles is carried out by the upper screen. Smaller particles and impurities are separated with the middle and bottom screens. In the P 12, the middle and bottom screens are arranged in parallel. In the F 12, with the help of an additional sliding floor and product flow distributor, the bottom screens can be arranged either in parallel or sequentially. Arranged sequentially, the middle screen acts as a relief screen for the bottom separation screen. The overflow then reaches the PETKUS dual channel final air separator, which has an ad- Seed cleaning for fine seed PETKUS Technologie GmbH | Roeberstr. 8 | 99848 Wutha-Farnroda | Germany | Phone:+49 36921

Open the catalog to page 1

Technical Data Capacity (Based on: wheat) Pre-cleaning Seed cleaning Intensive cleaning Capacity (Based on: Italian Rye Grass) Pre-cleaning Seed cleaning Length Width Height Weight Electrical power, without fan Volume with built in fan Volume with built in fan, rail or road transport Technical Data F 12 / P 12 Working width mm 1 200 No. of screen layers pcs. 3 Inclination of the upper screen ° 5 Inclination of the middle / lower screen ° 7 Screen area, total m² 5.04 Fan kW 5.5 - 11.0 Contact surface area cm² 1 014 Static ground pressure kN/m² 187 Revolution Hz 5.3 / 5.7 Horizontal dynamic...

Open the catalog to page 2All PETKUS Technologie GmbH catalogs and technical brochures

-

Optical sorter OS T roeber

3 Pages

-

Pre-Cleaner V 12 / V 15

2 Pages

-

PETKUS K-Series

3 Pages

-

Indented Cylinder ZK / ZL

2 Pages

-

Continuous Flow Dryer DW

2 Pages

-

Gravity Table G f-series

2 Pages

-

Gravity Table Type G 20

2 Pages

-

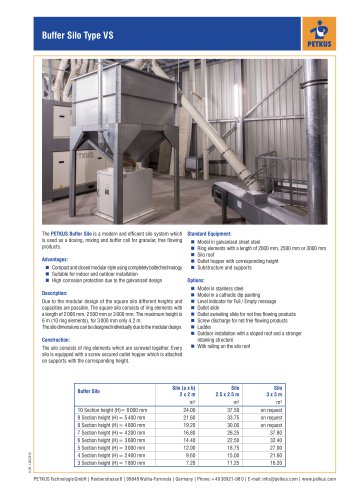

Buffer Silo Type VS

2 Pages

-

Smooth Wall Silo GWS

2 Pages

-

Profile Wall Silo Type PWS

2 Pages

-

Bucket Elevator Type BE 100

2 Pages

-

Continuous Flow Dryer DWU

2 Pages

-

SE 03

2 Pages

-

Dust Extraction System

2 Pages

-

Storage and Buffer Silo

2 Pages

-

Smooth Wall Silo

2 Pages

-

Wall Silo PWS

2 Pages

-

MultiCoater CM 100

2 Pages

-

Chemical Mixer Type 200

1 Pages

-

Continuous Flow Dryer DD

2 Pages

-

Indented Cylinder ZA

2 Pages

-

A-cleaner

2 Pages