Catalog excerpts

1 - Machine inlet 2 - Pre-sifting channel 3 - Screen cleaning system 4 - Screen layer 1 - upper screen shoe 5 - Screen layer 2 - upper screen shoe The purpose of the PETKUS U-Cleaner is the high-quality cleaning of grain, pulses, oilseeds and other free flowing products. The cleaner can be used for pre-, intensive and seed cleaning. The high standard of cleaning is achieved by a combination of the screening process and the air aspiration system. Advantages: Very high flexibility due to extensive setting options using product diverters and chutes High standard of cleaning and quality Simple and quick changing for various applications due to the modular design Highly effective cleaning of the screen surface by means of a ball cleaning system, and scraper chain, thus achieving a reduction of the overall machine length Also suitable for not free flowing products and sections with high debris Description: The product to be cleaned is evenly distributed and fed into the cleaner by an inlet hopper. The product is moved from the inlet hopper into the pre-aspiration. Light rejects, husk and dust are separated here. Afterwards, the product is transported into the top screen compartment with the two screen layers. The first screen layer is used for separating the coarse rejects. The second screen layer can either be used for separating coarse or light rejects depending on the desired mode of cleaning. The two screen layers in the bottom screen compartment can be used for separating coarse and light rejects or for calibrating the product by using the product diverters and chutes, depending on the mode of cleaning. The screened product is moved into the final aspiration. The product is sorted by its bulk density and light rejects such as hollow grains, foreign particles and dust are separated here. All screens are cleaned with balls which are placed under the screens.The first screen layer in the top screen compartment is additionally equipped with a scraper chain. 6 - Screen layer 3 - lower screen shoe 7 - Screen layer 4 - lower screen shoe 8 - Expansion chamber for pre- and main sifting channel 9 - Main sifting channel Construction: The U-Cleaner is equipped with an inlet hopper, one pre-aspiration and one final aspiration with a depositing chamber as well as two screen compartments with two screen layers vibrating in opposite directions. The various components of the machine (inlet hopper, discharge auger/ etc.) are operated by drive motors. Standard Equipment: Bolted frame made of painted sheet steel Screen compartments, pre-aspiration and final aspiration made of galvanized sheet steel Set of screens for screening diagram Drive units with gear motors Options: Conversion kits (screens and accessories) for various screening diagrams Scraper chain Vibrating infeed Discharge left or right Screensegment within exchangeable screen frame PETKUS Technologie GmbH | Roeberstrasse 8 |99848 Wutha-Farnroda | Germany | Phone:+49 36921-98 0

Open the catalog to page 1

Foundation plan Technical Data Capacity (Basis: wheat) Pre-cleaning Seed cleaning Industrial cleaning Drives Fan Screen shoe Machine inlet drum Discharge screw Cleaning device upper screen Air volume (wheat) Working width Screen surface Technical Data No. of screen layers Upper screen shoe Lower screen shoe No. of screen segments Upper screen shoe Lower screen shoe Total No. of screen segments Dimensions: A B C D Speed Load, horizontal (FH) Load, vertical (FV) Weight Technical alteration reserved. PETKUS Technologie GmbH | Roeberstrasse 8 | 99848 Wutha-Farnroda | Germany

Open the catalog to page 2All PETKUS Technologie GmbH catalogs and technical brochures

-

Optical sorter OS T roeber

3 Pages

-

Pre-Cleaner V 12 / V 15

2 Pages

-

PETKUS K-Series

3 Pages

-

Indented Cylinder ZK / ZL

2 Pages

-

Continuous Flow Dryer DW

2 Pages

-

Gravity Table G f-series

2 Pages

-

Gravity Table Type G 20

2 Pages

-

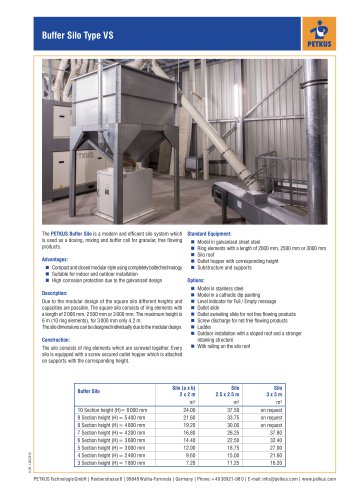

Buffer Silo Type VS

2 Pages

-

Smooth Wall Silo GWS

2 Pages

-

Profile Wall Silo Type PWS

2 Pages

-

Bucket Elevator Type BE 100

2 Pages

-

Continuous Flow Dryer DWU

2 Pages

-

SE 03

2 Pages

-

Dust Extraction System

2 Pages

-

Storage and Buffer Silo

2 Pages

-

Smooth Wall Silo

2 Pages

-

Wall Silo PWS

2 Pages

-

MultiCoater CM 100

2 Pages

-

Chemical Mixer Type 200

1 Pages

-

Continuous Flow Dryer DD

2 Pages

-

Indented Cylinder ZA

2 Pages

-

A-cleaner

2 Pages