Catalog excerpts

PLANT PROTECTION SPRAYERS Technology and working adaptability choices

Open the catalog to page 1

Modular Junkkari. PLANT PROTECTION SPRAYERS Junkkari sprayers have a modular structure. This means that from our body, pump, valve set and boom set models you can select a combination corresponding to your plant protection sprayer requirements. The modules are type-approved in/by the Finnish ????????????????? Vakola, in addition to which independent validation approves the ordered combination before delivery to the customer. All models include a clean water tank, stepping board, lights and reflectors according to road traffic regulations as standard supply Body and tank Accessories

Open the catalog to page 2

Lifting device sprayers The lifting device models can be built into more inexpensive packages equipped with the features of larger sprayers. When electrical and hydraulic functions are replaced with mechanical ones, a lower price level is achieved without compromising spraying quality. The agile lifting device model is particularly suited for spraying wedge-shaped, small and uneven lots. It also suits smaller tractors, since the sprayer's center of gravity is close to the tractor. Junkkari 3/900/12 Ekoline with foam marker equipment Towed sprayers The large tank of a towed sprayer enables...

Open the catalog to page 3

PLANT PROTECTION SPRAYERS BODY AND TANK The modern sprayer is made of light materials, such as plastics, aluminum and tube beam structures to keep the dead weight low. The tank is of durable MDPE plastic. The filling point is placed at the edge for easy filling. The suction pipe to the pump is located in the bottom well, which is an advantage particularly on uneven and inclined terrain: plant protectant flow to the pump is not interrupted if the sprayer tilts. When the plant protectant remains in the bottom well, cavitation can be avoided as well as suction malfunctions which are hard to...

Open the catalog to page 4

VALVE SET All Junkkari plant protection sprayers have a quadruple filtering system which efficiently cleans the liquid circulating in the sprayer. The first phase is coarse filtering, which takes place either in the filling port or in the suction device (accessory). The second phase, suction filtering, is after the tank on the suction side, before the pump. The third filtering is on the pressure side before the valve set in the self-cleaning pressure filter. The fourth filtering takes place in the block filters before the nozzles. The water is cleaned once with coarse filtering. The suction...

Open the catalog to page 5

PLANT PROTECTION SPRAYERS BOOM SET AND NOZZLES You can select either a mechanical or a hydraulic boom set for the Junkkari plant protection sprayer. In the hydraulic boom set you can also select either a light-weight boom set suitable for lifting device sprayers, or a wide boom set for large areas and contracting. The wide (18-21 m) hydraulic boom sets are recommended for use only with a towed sprayer with a front tank (2300 +500 liters). Mechanical boom set 12 m The mechanical boom set is inexpensive and it’s structure is light, sturdy and reliable. The boom set can be folded together...

Open the catalog to page 6

Greater efficiency and practicability EXTENSIVE ACCESSORY SELECTION Foam marker - an electrical compressor mixes air and marker fluid into foam in the nozzle. Electrical boom set tilting cylinder - helps the stabilizer to balance the boom set to the desired angle in relation to the horizon Wash nozzle - eases tank cleaning Foam marker Manual spraying bar - you can spray areas you cannot reach with a sprayer manually, e.g. spaces between A poles Suction device - the suction device draws water efficiently into the tank with a pump Mechanical boom lift and stabilizer - accessory for a...

Open the catalog to page 7

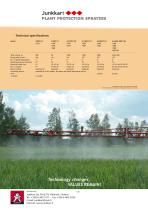

PLANT PROTECTION SPRAYERS Technical specifications Model Tank volume (l) Pump yield (l/min) No. of pump diaphragms Working pressure (max bar) Boom set width (m) No. of nozzles Boom folding Launching device Tires 13.6x38" ©Junkkari Oy 2007. Information may change. The factory reserves the right to changes without pre-warning. Technology changes, VALUES REMAIN! Manufacturing Junkkari Oy, FI-62375 Ylihärmä, Finland Tel. +358 6 483 5111 Fax +358 6 483 5295 E-mail: junkkari@msk.fi Internet: www.junkkari.fi

Open the catalog to page 8All Reikälevy Oy catalogs and technical brochures

-

NEW CROP SRPAYERS

2 Pages