Catalog excerpts

hnology ovative tec inn g t harvestin Sugar Bee for

Open the catalog to page 1

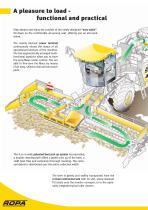

A pleasure to load functional and practical Step aboard and enjoy the comfort of the newly designed “euro-cabin”. Sit down on the comfortable air-sprung seat, offering you an all-round vision. The clearly laid-out colour terminal continuously shows the status of all operational functions of the machine. The two ergonomically arranged multifunctional joysticks allow you to have the euro-Maus under control. You are able to fine-tune the Maus by means of an easy, selector dial and two touch pads. The 8.70 m wide patented beet pick up system incorporating a double cleaning path offers a gentle...

Open the catalog to page 2

The transfer conveyer or the speed-adjustable spiral roller cleaner with its beet flow nylon deflector tubes can be installed in your machine depending on the cleaning intensity required in your area. This ensures that the beet get to the factory with only the minimum soil tare. The elevator can be turned right or left and has a loading reach of up to 11.50 m (standard elevator) or 13 m (extended elevator). The loading height is up to 6 m. Large ditches or hedges can be easily bridged. It is your ‘long arm’ when it comes to loading beet. The economical 220kw (299 hp) linear Mercedes Benz...

Open the catalog to page 3

Pick Up System Careful collection, extreme intensive cleaning The unique, 8.70 m wide ROPA pick up system divides the beet clamp evenly to the right and to the left. A nose cone, eccentrically driven, shakes up the clamp face and distributes the beet flow evenly. This concept minimizes the power requirement of the machine’s forward speed. Clearance underneath the in-feed web and an even soil distribution across the entire collection width offer significant advantages to this concept. End of clamp collector arm - proportional control valves - operating with left joystick Finger rollers...

Open the catalog to page 4

Double cleaning path – conical roller separates the beet flow All rollers serially hard welded (except conic roller) Skids and pressure control on the outer and central parts of the pick up unit determine the working depth. Setting is done via the joystick. For monitoring the operating depth a colour camera with spotlight has been installed underneath the nose cone allowing for the depth to be optimised and maintained from the cabin via a LCD colour monitor. This prevents loss and guarantees a clean collection as well as minimum power requirement. Efficient removal of soil, leaf and...

Open the catalog to page 5

Additional Cleaning Highest loading capacity – careful additional cleaning Beet conveying in the machine The beet protecting ROPA in-feed web with its maximum loading capacity and its soft PU cleats conveys the beet swiftly and gently underneath the cabin to the next cleaning unit. The beet flow can be comfortably monitored from the swivel seat. When the in-feed web switches off, pick up unit and forward drive are also automatically stopped. In-feed web with durable PU-collection cleats Between the in-feed web and the elevator there is the option for a continental web conveyer cleaner or a...

Open the catalog to page 6

50 p to 5 hour u per onnes t cal maxi Spiral roller cleaner Transfer conveyer cleaner Wider ditches can be bridged. The loading height is up to 6 m allowing lorries to stand on higher ground. Conveyor webs are equipped with a fast gear so that soil sticking to the continental web conveyers can be removed by centrifugal force. A hydraulically adjustable cross shaft axle at the rear ensures that beet collection is always carried out parallel to the ground to prevent the machine from turning over. By weighting the fuel tank with an additional steel plate the machine achieves a superb stability...

Open the catalog to page 7

The euro Cabin is specially developed by ROPA to combine modern design, first class overview and effective noise reduction all resulting in an ergonomic and comfortable work place. A smoothly curved windscreen provides an excellent all round view. Complemented by a particular low-line vision this gives the operator an unobstructed view over the entire operational width from an ergonomically correct seating position. An optimal view over picking up and loading functions without the need to adjust the sitting position means working ergonomically without tiring even on long working days. This...

Open the catalog to page 8

/77Z777 The radio is practically and prominently integrated into the cabin ceiling, as are the switches for the side windscreen wipers, the 22 super beam head lights and the main fuses. The LCD colour terminal for monitoring the pick-up depth or the optionally available elevator camera occupies a prime position in the operator’s range of vision.

Open the catalog to page 9

The right hand joystick activates all the important loading functions, controls the picking-up depth and separately sets into motion all the individual drive units as well as saving them. The entire operation of the machine rests in one hand of the operator whilst he has the other hand free for using the radio or telephone. It does not matter whether loading takes place on the right or on the left, control of the loader is always the same, the loading direction only is changed with the joystick. The left hand joystick operates all the functions of the proportionally controlled collector arm...

Open the catalog to page 10

⑧ The colour monitor is integrated into the control panel in the cabin enabling the operator to be continuously informed of the operational status of the machine from his range of vision. Some information is given acoustically as well as optically. He can therefore constantly read off all data crucial for the operation processes of the machine: (green = ok; orange = check; red = alarm). All data from the euro Maus are saved separately after road transport and after loading procedures. An integrated fuel consumption monitor allows for a cost assessment to be made per loading hour. An...

Open the catalog to page 11

Road transport Highest manoeuvrability – swift change over The euro Maus can be changed from transport to work mode in as little as 2 minutes without the operator having to leave the cab. This facilitates swift and easy movement between clamps. Short set up times lead to highest efficiency when loading beet. When in automotive mode on the road the euro Maus is at all times driven at the required speed with low engine revolutions and lowest possible fuel consumption. When the power pedal is depressed propulsion and engine revolution are jointly activated. An electro-pneumatic gear takes over...

Open the catalog to page 12All ROPA Fahrzeug- und Maschinenbau GmbH catalogs and technical brochures

-

Tiger 6S

12 Pages

-

Keiler II

27 Pages

-

Haulm topper KS 475

5 Pages

-

PANTHER 2S

15 Pages

-

ROPA

19 Pages

-

NawaRo-Maus

4 Pages

-

TIGER 6

48 Pages

-

Panther 2

44 Pages

-

ROPA Maus 5

24 Pages

-

Keiler 1

8 Pages

-

euro-Maus 4

16 Pages

-

euro Tiger V8-4

20 Pages

-

Panther

40 Pages

-

TIGER 5

40 Pages