Catalog excerpts

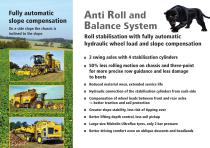

Anti Roll and Balance System Uneven surfaces (e.g. when driving along a wheeling) are only half transmitted to the frame thanks to roll stabilisation of the chassis! Optimal surface contour adaptation with two swing axles with stabilisation cylinders Cabin, bunker and chassis remain horizontal

Open the catalog to page 2

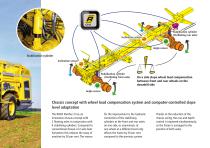

Inclination sensor Stabilisation cylinder (Oscillating rear axle) ° ° Angle sensor Stabilisation cylinder Inclination sensor ° Stabilisation cylinder (Oscillating front axle) ° On a side slope wheel load compensation between front and rear wheels on the downhill side Angle sensor Chassis concept with wheel load compensation system and computer-controlled slope level adaptation The ROPA Panther 2 has an innovative chassis concept with 2 floating axles in conjunction with 4 stabilising cylinders. Compared to conventional chassis of 2-axle beet harvesters this reduces the sway of machine by 50...

Open the catalog to page 3

Fully automatic slope compensation On a side slope the chassis is inclined to the slope. Anti Roll and Balance System Roll stabilisation with fully automatic hydraulic wheel load and slope compensation 2 swing axles with 4 stabilisation cylinders 0% less rolling motion on chassis and three-point 5 for more precise row guidance and less damage to beets Reduced material wear, extended service life Hydraulic connection of the stabilisation cylinders from each side of wheel loads between front and rear axles -> better traction and soil protection Greater slope stability, less risk of tipping...

Open the catalog to page 5

The sporty and agile Panther ■ TOP manoeuvrability with 60° articulation angle ■ Optimal articulation position - 1650 mm behind the front axle ■ The chassis tilts to the centre of the circle during fast travel around curves ■ Easy harvesting, even on small fields ■ Small turning circle ■ 40 km/h road travel at only 1265 rpm.

Open the catalog to page 7

Ergonomics and comfort, the driver is at the centre. R-Cab in the new design The easy-care, pleasant and attractive interior of the new cabin guarantees the most comfortable operation. There are generously dimensioned shelves, storage compartments and plenty of space around the driver. Standard equipment includes a ROPA Evolution Grammer comfort seat with heating and active ventilation and also a cool box under the comfortable passenger seat. Extremely powerful fully LED working lights turn night into day. R-View video system (optional) The rear part of the machine is displayed on the...

Open the catalog to page 9

Select important working functions Grouped functions for intuitive selection and adjustment of all important functions during operation for quick and clear adjustment. Intuitive dual operating concept - ROPA combines under the name R-Concept its new intuitive operating philosophy. The large 12.1 inch touch screen is the information and command centre of the machine. From here the operator monitors the entire machine, receives information about operating conditions and performance data, adjusts functions and the working results of the machine. Dual operation either with fingertip on the...

Open the catalog to page 10

#7 Direct Directly in the terminal menu Direct access to main menus and to detailed machine settings and data query in submenus. Main menu Light control Special functions'----"" Operating data Lights menu One or all working lights can be switched on only with a fingertip on the touch-terminal. And again a one fingertip is enough to back up and recall three different lighting programs. Light control Automatic folding A touch of the button is enough to "transform" the Panther 2 automatically from road drive mode to field mode. Unloading conveyor, one metre wide ring elevator, bunker auger and...

Open the catalog to page 11

Powerful LED lights turn night to day 10,000 lumens on the driver's cabin The redesigned and very spacious R-Cab driver's cabin has been significantly upgraded and is suspended on hydrobushings. It is oriented to the driver, who has the best overview of the redeveloped lifting unit from a physiologically appropriate and comfortable seating position.

Open the catalog to page 13

ROPA RES rubber-defoliator The both fully hydraulic driven cleaning rotors can be adjusted in the rotation speed and height independently from the other – unique! Various settings can be stored and accessed on the joystick using a memory function.

Open the catalog to page 14

Tiger 6, defoliator on Panther 2 identical Tiger 6, defoliator on Panther 2 identical RAS integral leaf mulcher ROPA all-round defoliator with leaf ejection ROPA all-round defoliator with integrated leaf mulcher The beet leaves are shredded and transported by a leaf scroll to the leaf plate, which spreads them over the harvested area. A press of the button in the cabin switches the machine. An optional leaf collection conveyor can be installed for harvesting beet leaves (biogas or dairy). The beet leaves are shredded and deposited between the rows. A press of the button in the cabin...

Open the catalog to page 18

RIS - ROPA integral defoliator ROPA integral defoliator - standard model for normal harvesting conditions Leaves from the beet crowns are mulched with robust defoliator knives and spread between the rows. Therefore, beet leaves with all their nutrients are evenly delivered to the soil, the optimal basis for further soil cultivation as green waste is quickly converted to humus.

Open the catalog to page 19

Micro-Topper The sharp knife cuts off leaves, nothing is wasted, no beets are cut too low.

Open the catalog to page 20

Weight-optimised RR lifter with single-row adjustment The RR lifting unit is equipped with counter-rotating oscillating shares, seven lifting rollers, completely maintenance-free hydraulic stone protection and single-row adjustment of the lifting depth. The 850 mm large depth-control wheels combined with the intelligent three-point suspension guarantee accurate depth control of the lifter. Maintenance costs are minimised with adjustable taper roller bearings in transmissions and the oscillating share drive.

Open the catalog to page 24

Convenient maintenance position - RR lifting unit The convenient maintenance position is the best possible position for inspection and service of defoliator knives, scalper knife and lifting shares. The defoliator and lifting group can be raised to 90 degrees at the touch of a button from the cabin or the ground. The engine can be started by pressing a button on the lifting unit to set the desired maintenance position.

Open the catalog to page 26All ROPA Fahrzeug- und Maschinenbau GmbH catalogs and technical brochures

-

Tiger 6S

12 Pages

-

Keiler II

27 Pages

-

Haulm topper KS 475

5 Pages

-

PANTHER 2S

15 Pages

-

ROPA

19 Pages

-

NawaRo-Maus

4 Pages

-

euro-Maus 3

16 Pages

-

TIGER 6

48 Pages

-

ROPA Maus 5

24 Pages

-

Keiler 1

8 Pages

-

euro-Maus 4

16 Pages

-

euro Tiger V8-4

20 Pages

-

Panther

40 Pages

-

TIGER 5

40 Pages