Catalog excerpts

MASCHINE MACHINE DESOF THE YEAR 2015 JAHRES 2015 Superior class.

Open the catalog to page 1

MASCHINE MACHINE DESOF THE YEAR 2015 JAHRES 2015 ✔ proven innovative design ✔ harvesting the complete beet crop ✔ .00 m width for harvesting 3 without beet losses ✔ excellent reliability – rugged construction ✔ durable and with excellent residual value ✔ ew chassis concept - more operational n performance in wet conditions ✔ levelling on slopes greater driver comfort ✔ new user-friendly cabin ✔ large tank capacity – high daily performance ✔ reduced fuel consumption ✔ less wear and tear ✔ increased soil protection

Open the catalog to page 3

Soil-protective hydraulic chassis system with new tyre technology only 1.4 bar tyre inflation pressure for sustainable land management Awarded with silver medal at Agritechnica 2015.

Open the catalog to page 4

ROPA R-Soil Protect is a soil-protective, hydraulic chassis system with new MICHELIN CerexBib tyre technology providing for the first time just 1.4 bar tyres inflation pressure for efficient root crop harvesting. Thanks to the networking of all three hydraulically supported axles, wheel load is balanced between all wheels and load peaks on a wheel are consistently avoided. The blend of load-balancing, hydraulic chassis with the new generation tyres; MICHELIN IF1000/55 R32 CerexBib, results in larger contact surface with significantly reduced contact pressure. ROPA R-Soil Protect Innovations...

Open the catalog to page 5

Hydraulic connection of the stabilization cylinders at front and rear axles from the each side Hydraulic chassis system - roll stabilization with load compensation - applied for patent Specifically for the Tiger 5, ROPA has developed an innovative chassis concept with an oscillating front axle in conjunction with 2 hydraulically supported rear axles. Compared to previous chassis of 3-axle beet harvesters (the central axle is fixed to the frame) this reduces the sway of machine by one third! It is achieved by the hydraulic connection of the cylinders at the front and rear axles of the one...

Open the catalog to page 6

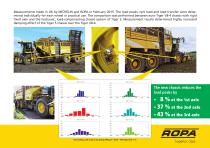

Measurements made in UK by MICHELIN and ROPA in February 2015. The load peaks, tyre load and load transfer were determined individually for each wheel in practical use. The comparison was performed between euro-Tiger V8-4 chassis with rigid fixed axle and the hydraulic, load-compensating chassis system of Tiger 5. Measurement results determined highly increased damping effect of the Tiger 5 chassis over the Tiger V8-4. The new chassis reduces the load peaks by Tiger 4 - axle 2 8 % at the 1st axle • 37 % at the 2nd axle • 43 % at the 3rd axle • Horizontally: peak loads in kg during lifting...

Open the catalog to page 7

Slope compensation up to 10% - gravity centre / ground pressure are compensated The automatic levelling system using six hydraulic cylinders and sensors is unique among 3-axle beet harvesters. The chassis is kept completely horizontally for up to 10 percent side slope. The gravity centre and, thus, the load of the wheels on the slope bottom side are shifted to the slope top side. The track depth of the wheels on the slope bottom side is substantially reduced, the infiltration capacity is retained, thus significantly reducing erosion risk during heavy rains. Slope stability and traction are...

Open the catalog to page 8

Hydraulic chassis, automatic slope compensation Superior class.

Open the catalog to page 9

Direct power transmission with cardan shafts ensures even traction on all wheels at very high torque Unique on the market of 3-axle sugar beet harvesters; the Tiger 5 has a direct power transmission using directly linear situated cardan shafts from traction drive to both rear axles and front axle. This is a great advantage for increased traction in changing or difficult soil and harvesting conditions. Thanks to the hydraulic chassis the load is always distributed evenly. Thus, lead or lag between the axles is eliminated. Stepless CVR gearbox for efficient power transfer This new stepless...

Open the catalog to page 10

Superior class.

Open the catalog to page 11

Significantly larger ground contact area for sustainable soil protection Good soil protection is maintained by Michelin 800/70 R38 Ultraflex tyres at the front axle and optional Michelin CerexBib IF1000/55 R 32 CFO tyres at the rear axles. Even with a full bunker of about 43 m³ / 30 t, the soil is protected along with improved damping characteristics at only 1.4 bar of tyre inflation pressure in all six wheels. Less ground pressure at the same loading 10800 kg cycl. at tokm/h Reason 15 believe Footprint measurement at 10 000 kg Tyre inflation pressure 2.4 bar Ground contact area measurement...

Open the catalog to page 12

MASCHINE MACHINE DESOF THE YEAR 2015 JAHRES 2015 Superior class.

Open the catalog to page 13

Master of extreme terrain

Open the catalog to page 14

ROPA rubber-defoliator PES The two fully hydraulic driven cleaning rotors can be adjusted in rotational speed and height – unique! Various settings can be stored and accessed on the joystick using a memory function.

Open the catalog to page 16

ROPA all-round defoliator Leaf ejection ROPA all-round defoliator Integral leaf-layer

Open the catalog to page 18

ROPA integral defoliator

Open the catalog to page 19

Superior class.

Open the catalog to page 21

Non-jamming PR lifting unit with hydraulic stone protection The PR2h lifting unit is equipped with counter-rotating oscillating shares and completely maintenance-free hydraulic stone protection. The 900 mm large depth-control wheels combined with the intelligent three-point suspension guarantee accurate depth control of the lifter. Minimum maintenance costs are required thanks to adjustable taper roller bearing in drives and oscillating share drive. Micro-Topper The sharp flail cuts off leaves, nothing is wasted, no beets are cut too low.

Open the catalog to page 22

Efficiency and power with XL lifting units Significantly higher harvesting area with the larger XL head reduces fuel consumption resulting in lower costs over the harvest season. Less passes and manoeuvres also contribute to better soil protection. Thanks to the possibility of offloading while harvesting, performance of up to 3 ha per hour can be achieved under favourable harvest conditions.

Open the catalog to page 26

Transfer Wi-Fi Connect Transfer Wi-Fi Connect

Open the catalog to page 28

New cabin and operating concept The very spacious R-Cab has been significantly upgraded for the model year 2016. First of all, it is oriented around the driver, who can enjoy the best overview of the newly developed PR2 lifting unit from physiologically appropriate and comfortable seating position. A pleasant and spacious new cabin guarantees the most comfortable operation. Generously dimensioned shelves, storage compartments provide plenty of storage space around the driver. Even a cooling box is integrated under the passenger seat. Extremely powerful fully LED working lights turn night...

Open the catalog to page 29All ROPA Fahrzeug- und Maschinenbau GmbH catalogs and technical brochures

-

Tiger 6S

12 Pages

-

Keiler II

27 Pages

-

Haulm topper KS 475

5 Pages

-

PANTHER 2S

15 Pages

-

ROPA

19 Pages

-

NawaRo-Maus

4 Pages

-

euro-Maus 3

16 Pages

-

TIGER 6

48 Pages

-

Panther 2

44 Pages

-

ROPA Maus 5

24 Pages

-

Keiler 1

8 Pages

-

euro-Maus 4

16 Pages

-

euro Tiger V8-4

20 Pages

-

Panther

40 Pages