Catalog excerpts

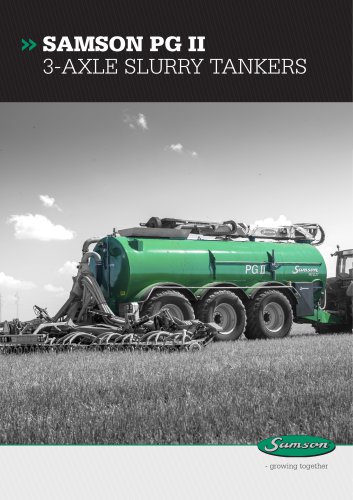

SAMSON PG II 3-AXLE SLURRY TANKERS - growing together SAMSON AGRO A/S • PG II 3-axle slurry tankers

Open the catalog to page 1

SAMSON 3-AXLE PG II slurry tankers With the 3-axle slurry tankers, SAMSON AGRO has developed a series of field slurry tankers of very high capacity and quality. The series additionally offers many new exciting functions designed to make it an attractive choice for many years to come. The series was launched by SAMSON AGRO for the 2014 slurry season. on the use of agricultural machinery on public roads, both for With the 3-axle slurry tankers, SAMSON AGRO has developed The tank is placed horizontally on two strong through-going a series of field slurry tankers of very high capacity and...

Open the catalog to page 2

A camera (optional extra) fitted underneath the pump tower is The new pump tower has a very compact design. The reflux pipe, another new feature. It ensures a good view for the driver during hydraulic hoses, etc., are now better integrated inside the pump filling and makes it very easy to fold the pump tower back into tower and therefore better protected. The pump tower consists of place once the tank is full. The driver can oversee the operation only two moving parts compared with three parts in the previous without the need to turn around in the seat. The long working versions of the...

Open the catalog to page 3

SAMSON AGRO has developed a new powerful ejector-vacuum pumping system (simply called the ejector in the following). This is a robust pump that can pump any kind of liquid, needs very little maintenance, has very low operating costs and does not lose its effect over time. The ejector uses the so-called Venturi effect, which is named after the Italian physicist Giovanni Battista Venturi who described the effect back in the 19th century. In simple terms, the Venturi effect is the acceleration of a fluid when it is compressed. This takes place, for example, if a fluid carried in a pipe has to...

Open the catalog to page 4

Sketch SAMSON AGRO’s ejektor More than just an ejector In order to drive the SAMSON AGRO ejector, a small volume of slurry needs to be retained in the slurry tanker. The slurry is retained in a reservoir within the tanker. If the ejector is not used, this retainer function can be disconnected. The ejector can be used for filling the tanker under its own power via a valve at the side of the tanker or for vacuum attachment of centrifugal pumps to either the fixed filling pump, the SAP or pump tower. The use of centrifugal pumps results in a higher performance of the filling system. The...

Open the catalog to page 5

Advantages of the new SAMSON AGRO ejector Inline-ejector principle: • he tank on the vehicle is not exposed to a vacuum. This T ensures a light construction • No vacuum in the tank means that the slurry does not Foreign objects: • Copes well with all forms of foreign objects in the slurry: stones, bits of metal, plastic, wood and wire/string from straw bales • eeds no stone trap or slicers for chopping the slurry and N foreign objects • o unplanned stoppages or regular maintenance because N of sharp objects in the slurry expand during filling and ensures that the tank is 100% full when...

Open the catalog to page 6

SAMSON AGRO A/S • PG II 3-axle slurry tankers

Open the catalog to page 7

Several Filling options PG II slurry tankers can be filled in several ways. These filling options can be combined in different ways. Please check the price list for the different combinations. But the different options are: EXTERNAL FILL External fill via a funnel PUMP TOWER Pump tower with telescopic arm SAMSON AGRO A/S • PG II 3-axle slurry tankers

Open the catalog to page 8

Hose connector Hose with pump Single-articulated SAP arm (SAP1) with or without pump SAMSON AGRO A/S • PG II 3-axle slurry tankers

Open the catalog to page 9

Double-articulated SAP arm (SAP2) with or without pump Direct filling from underground storage of slurry Filling by filling funnel SAMSON AGRO A/S • PG II 3-axle slurry tankers SAP2 with a filling hose mounted

Open the catalog to page 10

Completely new filling possibilities with an ejector The ejector pump can be combined with different filling solutions. Filling can take place via a hose connector or a hose and Emptying another slurry tanker or truck with slurry pump on the side of the slurry tanker, via a single-articulated SAP arm (SAP1) with or without a pump, via a double-articulated SAP arm (SAP2) with or without a pump, or via a pump tower with a suction plug/ connection. The SAP2 arm on the PG II slurry tanker enables the user to empty other tankers or trucks not equipped with a discharge pump. The user can also...

Open the catalog to page 11

SAMSON AGRO Control systems SAMSON AGRO has expanded the product program of controlling systems, whereby the customers are offered both technical simple controlling systems with only few hydraulic functions and up to more comprehensive controlling systems with lots of hydraulic functions. You can read more about these different controlling systems in separate information materials. The well-known SlurryMaster6000 control system from SAMSON AGRO. Markedsforskelle på udstyret Please be aware that on the different markets there may be variations in what is defined as standard equipment and...

Open the catalog to page 13

Standard 1. Adjustable suspended drawbar with jack (410x180 mm is standard) are dimensioned to comply with even the strictest legal requirements. The large 15-degree steering angle of the axles combined A new feature of the PG II slurry tankers is an adjustable with the compact 900 mm wide chassis results in a very ma- drawbar with suspension. The drawbar absorbs shocks from noeuvrable slurry tanker. This reduces the damage to plants both tractor and trailer, giving a more even ride. It also in- while driving in the field and the wear on tyres when driving creases the lifespan of the slurry...

Open the catalog to page 14

All PG II slurry tankers are fitted with LED lights that are There is space for as many as 14 hydraulic couplings and highly reliable and require a minimum of maintenance. Mud- central lubrication points on the back of the slurry tanker. guards are also standard on all slurry tankers to avoid splash The couplings are placed on each side of the slurry tanker from tyres onto implements. under the rear lights to avoid the need to get in between tanker and implement when attaching hydraulic hoses. They A Waltersheid PTO drive shaft is standard on all tankers. This are of the push-pull type...

Open the catalog to page 15All SAMSON AGRO A/S catalogs and technical brochures

-

SAMSON PG II Genesis

2 Pages

-

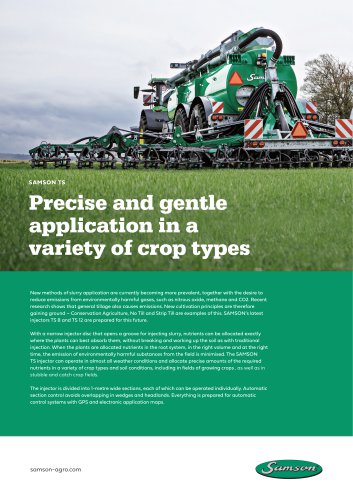

SAMSON TS

2 Pages

-

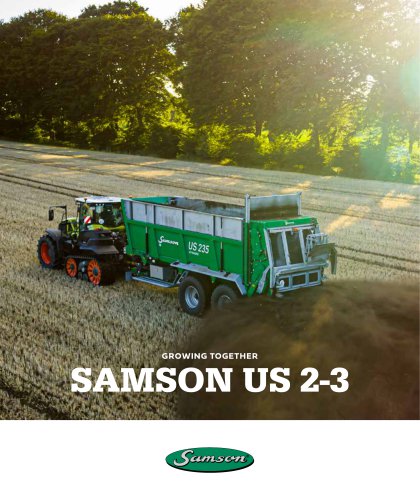

SAMSON US 2-3

11 Pages

-

PG

8 Pages

-

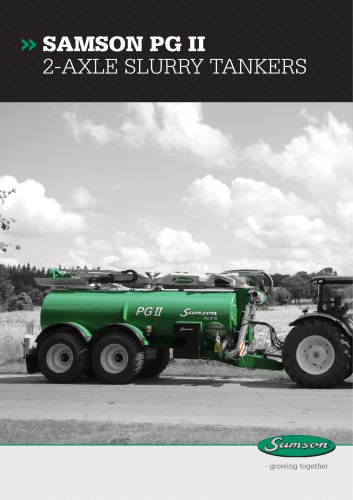

PG II 2-axle

20 Pages

-

SG

8 Pages

-

SP

8 Pages

-

FLEX

12 Pages

-

SAMSON IMPLEMENTS

24 Pages

-

The little Green guide

28 Pages