Catalog excerpts

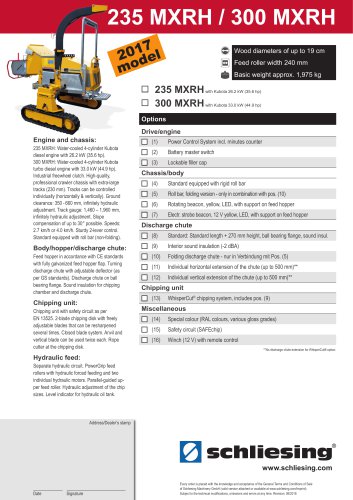

Wood diameters of up to 19 cm Feed roller width 240 mm Basic weight approx. 1,975 kg □ 235 MXRH with Kubota 26.2 kW (35.6 hp) □ 300 MXRH with Kubota 33.0 kW (44.9 hp) OptionsDrive/engine Engine and chassis: □ (1) Power Control System incl. minutes counter 235 MXRH: Water-cooled 4-cylinder Kubota diesel engine with 26.2 kW (35.6 hp). 300 MXRH: Water-cooled 4-cylinder Kubota turbo diesel engine with 33.0 kW (44.9 hp). Industrial freewheel clutch. High-quality, professional crawler chassis with extra-large tracks (230 mm). Tracks can be controlled individually (horizontally & vertically). Ground clearance: 350 - 660 mm, infinitely hydraulic adjustment. Track gauge: 1,460 - 1,960 mm, infinitely hydraulic adjustment. Slope compensation of up to 30° possible. Speeds: 2.7 km/h or 4.0 km/h. Sturdy 2-lever control. Standard equipped with roll bar (non-folding). Body/hopper/discharge chute: (2) Battery master switch Chassis/body □ (4) Standard equipped with rigid roll bar □ (5) Roll bar, folding version - only in combination with pos. (10) □ (6) Rotating beacon, yellow, LED, with support on feed hopper □ (7) Electr. strobe beacon, 12 V yellow, LED, with support on feed hopper Discharge chute □ (8) Standard: Standard length + 270 mm height, ball bearing flange, sound insul. Feed hopper in accordance with CE standards □ (10) Folding discharge chute - nur in Verbindung mit Pos. (5) with fully galvanized feed hopper flap. Turning discharge chute with adjustable deflector (as per GS standards). Discharge chute on ball bearing flange. Sound insulation for chipping chamber and discharge chute. Chipping unit: Chipping unit with safety circuit as per EN 13525. 2-blade chipping disk with freely adjustable blades that can be resharpened several times. Closed blade system. Anvil and vertical blade can be used twice each. Rope cutter at the chipping disk. (11) Individual horizontal extension of the chute (up to 500 mm)** □ (12) Individual vertical extension of the chute (up to 500 mm)** Chipping unit □ (13) WhisperCut® chipping system, includes pos. (9) Miscellaneous □ (14) Special colour (RAL colours, various gloss grades) □ (15) Safety circuit (SAFEchip) □ (16) Winch (12 V) with remote control **No discharge chute extension for WhisperCut® option. Hydraulic feed: Separate hydraulic circuit. PowerGrip feed rollers with hydraulic forced feeding and two individual hydraulic motors. Parallel-guided upper feed roller. Hydraulic adjustment of the chip sizes. Level indicator for hydraulic oil tank. Address/Dealer’s stamp schliesing®www.schliesing.com Date Every order is placed with the knowledge and acceptance of the General Terms and Conditions of Sale of Schliesing Machinery GmbH (valid version attached or available at www.schliesing.com/Imprint) Subject to the technical modifications, omissions and errors at any time. Revisi

Open the catalog to page 1

235 MXRH 300 MXRH WNO*® Interesting options: Schliesing SAFEchip safety technology The wood chipper is in line with the safety instructions of DIN-EN 13525 0 Folding feed hopper as per CE standards, min. depth of 1,500 mm 0 Fully galvanized feed hopper flap □ Hopper dims. (interior): width = 1,040 mm, height = 960 mm 0 Chipping disk 0 655 mm, 35 mm thick 0 Closed blade system for a fast, safe and precise blade change 0 Freely adjustable blade settings 0 Hydraulic adjustment of the chip sizes 0 Blades can be resharpened up to approx. 10 times for a long service life 0 Anvil and vertical...

Open the catalog to page 2