Catalog excerpts

Special Machines and Robotics EXHOUSt Air SCWtter S/SteAW Drive Technology Explosion-Proof Systems and Value Technology Switchgear Construction Building-Services Technology Agricultural Technology

Open the catalog to page 1

Exhaust air purification for agriculture Headline and industry When it comes to clean exhaust air, we have the experts you need. Our long-standing experience and our own research and development work on multiphase exhaust air scrubber systems make us a qualified partner in this field. We offer you everything from a single source: > Support for approval procedures > System planning > System installation > Commissioning > Training > Maintenance

Open the catalog to page 2

Our EMMI exhaust air scrubber system Exhaust air purification plays a key role in the approval of animal house systems. Investing in an exhaust air scrubber system can make approval procedures much easier. In fact, it is not only an extremely effective means of reducing ammonia, dust and odours but it also increases acceptance in the surrounding area and protects the environment. For many years, SCHULZ Systemtechnik has been dealing with this subject matter and has specialised in highly energy-efficient purification systems. At the same time, we are constantly further developing our...

Open the catalog to page 3

System construction and control technology > Customised system construction > Container design (waterproof, chemical-resistant, no intermediate consumption on-site) When is it useful to build a multi-phase system? The exhaust air from most emission sources contains not only odour but also other exhaust air substances, such as ammonia and hydrogen sulphide, which must be removed from exhaust air. Multi-phase systems ensure effective and cost-efficient exhaust air purification. In each individual phase, a selective purification process takes place, which always leads to a considerably...

Open the catalog to page 4

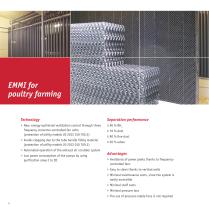

EMMI for poultry farming Our EMMI exhaust air scrubber system is divided into three purification areas (I to III), so that, in each case, only the necessary surface of the filter must be operated. The required purification phases are switched on or off only when emissions and exhaust air volume flows rise. This occurs, for example, on particularly hot days or when the animals have reached the end of the fattening process simultaneously. The fan units used are controlled through frequency converters. In this way, power peaks can be avoided and operating costs significantly reduced. The fact...

Open the catalog to page 5

EMMI for poultry farming Technology Separation performance > New, energy-optimised ventilation control through three frequency converter-controlled fan units (protection of utility models 20 2012 010 700.3) > Avoids clogging due to the tube bundle filling material (protection of utility models 20 2012 010 700.3) > Automated operation of the exhaust air scrubber system > Low power consumption of the pumps by using purification areas I to III ≥ 70 % dust ≥ 90 % fine dust ≥ 50 % odour Advantages > Avoidance of power peaks thanks to frequencycontrolled fans > Easy to clean thanks to vertical...

Open the catalog to page 6

EMMI for poultry farming tube bundle dust and NH3 separation Schematic representation of an exhaust air scrubber system for broiler chicken raw gas droplet separator filter wall odour separation acid storage container fresh water transfer pump water reservoir ball valve in the bypass circulating pump water reservoir I & II acid dosing pump for water reservoir II acid dosing pump for water reservoir I conductivity measurement dampening circuit of the filter wall odour separation nozzles for the dampening of filter wall I

Open the catalog to page 7

EMMI for pig farming The exhaust air arising from pig farming must be free from dust, odour and ammonia, in accordance with current legal requirements. Since the odour-eliminating microbiology is sensitive, we plan and construct exhaust air purification as a chemical/biological purification system. In fact, by using acids, ammonia can be highly effectively bound and thus removed from exhaust air. As a result, the subsequent biological phase can be carried out much more effectively. Furthermore, this configuration works immediately, with no need for long adaptation times. In pig farming, our...

Open the catalog to page 8

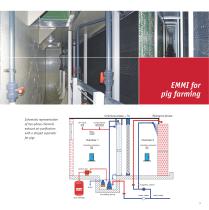

EMMI for pig farming Chemical phase + TA Schematic representation of two-phase chemical exhaust air purification with a droplet separator for pigs Biological phase chamber 2 chamber pressure chamber pressure acid pump magnetic valves drain circulating pump acid storage water meter fresh water

Open the catalog to page 9

EMMI for the industry Depending on individual requirements, in industrial application, a wide variety of substances must be removed from exhaust air, for example dust, odours or corrosive gases. In industrial plants, for example, a highly loaded process exhaust air flow must therefore be treated differently compared to that used for ambient air suction. This is only possible with multi-phase systems, which are planned and tailored according to customer requirements and adjusted depending on the exhaust air substances to be removed. Hence, exhaust air purification can be designed for almost...

Open the catalog to page 10

EMMI for the industry Technology > Sour, alkaline, oxidative and biologically combinable > Purification of process and ambient air > Exhaust air dust removal > Implementation of exhaust air scrubber systems in plastic and GRP > Safe and proven technology thanks to a long-standing experience in various sectors, such as agricultural technology, food technology, slaughter and recycling facilities, biogas plants and digestate drying > Strong fluctuating volume flows and emission loads are proven to be safely controllable Separation performance According to requirements, for example: ≥ 95 % NH3...

Open the catalog to page 11

SCHULZ Systemtechnik GmbH info@schulz.st • www.schulz-gruppe.st

Open the catalog to page 12All SCHULZ Systemtechnik GmbH catalogs and technical brochures

-

Mixed feed industr

5 Pages

-

Poultry farming

20 Pages

-

Pig farming

10 Pages

-

AgriFarmControl

24 Pages