Catalog excerpts

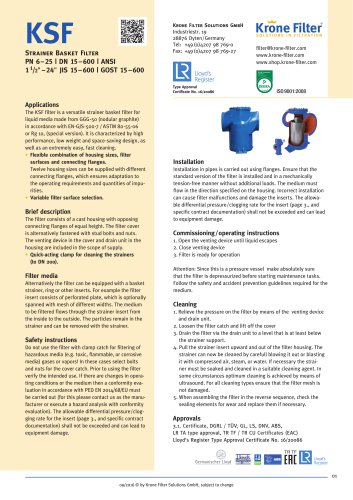

Strainer Basket Filter PN 6 – 25 | DN 15 – 600 | ANSI 1 1/2" – 24" JIS 15 – 600 | GOST 15 – 600 Type Approval Certificate No. 16/20086 filter@krone-filter.com www.krone-filter.com www.shop.krone-filter.com Applications The KSF filter is a versatile strainer basket filter for liquid media made from GGG-50 (nodular graphite) in accordance with EN-GJS-500-7 / ASTM 80-55-06 or Rg 10, (special version). It is characterized by high performance, low weight and space-saving design, as well as an extremely easy, fast cleaning. • Flexible combination of housing sizes, filter surfaces and connecting flanges. Twelve housing sizes can be supplied with different connecting flanges, which ensures adaptation to the operating requirements and quantities of impurities. • Variable filter surface selection. Brief description The filter consists of a cast housing with opposing connecting flanges of equal height. The filter cover is alternatively fastened with stud bolts and nuts. The venting device in the cover and drain unit in the housing are included in the scope of supply. • Quick-acting clamp for cleaning the strainers (to DN 200). Filter media Alternatively the filter can be equipped with a basket strainer, ring or other inserts. For example the filter insert consists of perforated plate, which is optionally spanned with mesh of different widths. The medium to be filtered flows through the strainer insert from the inside to the outside. The particles remain in the strainer and can be removed with the strainer. Safety instructions Do not use the filter with clamp catch for filtering of hazardous media (e.g. toxic, flammable, or corrosive media) gases or vapors! In these cases select bolts and nuts for the cover catch. Prior to using the filter verify the intended use. If there are changes in operating conditions or the medium then a conformity evaluation in accordance with PED EN 2014/68/EU must be carried out (for this please contact us as the manufacturer or execute a hazard analysis with conformity evaluation). The allowable differential pressure / clogging rate for the insert (page 3., and specific contract documentation) shall not be exceeded and can lead to equipment damage. Installation Installation in pipes is carried out using flanges. Ensure that the standard version of the filter is installed and in a mechanically tension-free manner without additional loads. The medium must flow in the direction specified on the housing. Incorrect installation can cause filter malfunctions and damage the inserts. The allowable differential pressure / clogging rate for the insert (page 3., and specific contract documentation) shall not be exceeded and can lead to equipment damage. Commissioning / operating instructions 1. Open the venting device until liquid escapes 2. Close venting device 3. Filter is ready for operation Attention: Since this is a pressure vessel make absolutely sure that the filter is depressurized before starting maintenance tasks. Follow the safety and accident prevention guidelines required for the medium. Cleaning 1. Relieve the pressure on the filter by means of the venting device and drain unit. 2. Loosen the filter catch and lift off the cover 3. Drain the filter via the drain unit to a level that is at least below the strainer support. 4. Pull the strainer insert upward and out of the filter housing. The strainer can now be cleaned by carefull blowing it out or blasting it with compressed air, steam, or water. If necessary the strainer must be soaked and cleaned in a suitable cleaning agent. In some circumstances optimum cleaning is achieved by means of ultrasound. For all cleaning types ensure that the filter mesh is not damaged. 5. When assembling the filter in the reverse sequence, check the sealing elements for wear and replace them if necessary. Approvals 3.1. Certificate, DGRL / TÜV, GL, LS, DNV, ABS, LR TA type approval, TR TF / TR CU Certificates (EAC) Lloyd‘s Register Type Approval Certificate No. 16/20086 TR TF Type Approval Certificate No. 16/20086 09/2016 © by Krone Filter Solutions GmbH, subj

Open the catalog to page 1

Standard Connections for differential pressure indicator/switch G 1/4" Basket strainer KSF combination version (clamp version pre-drilled), can be converted by using stud bolts. * Special version ** For screws dependent on DN and medium to PN 25 *** Flowrate limited by inlet flange 09/2016 © by Krone Filter Solutions GmbH, subject to change

Open the catalog to page 2

Filter insert design Filter mesh Filter insert dp pressure Filter cover Venting device Draining unit Connection Materials: Housing and cover Cover seal Perforated plate/mesh Extras Additional filter Heater Zinc protection Differential pressure indicator Body/Cover Surface treatment internal: external: Design/Certification * Depends on size of body Standard version Strainer insert or ring strainer 20-1,000 pm (microns) Stainless steel mesh 1,5-10 mm perforated plate, round pitch Allowable differential pressure filter insert 1.5 bar DN 15-200 combination cover with clamp catch or cover with...

Open the catalog to page 3

Heat flanges and differential pressure indicator On request the filter can be fitted with heat flanges in the floor area as shown in the sketch. The use of heaters requires the use of ring strainers. KSF filter with differential pressure indicator Differential pressure indicator The KSF ”family“ from size 1 to size 11 04 09/2016 © by Krone Filter Solutions GmbH, subject to change

Open the catalog to page 4

Lloyd's Register Type Approval Certificate This is to certify that the undernoted product(s) has/have been tested with satisfactory results in accordance with the relevant requirements of the Lloyd's Register Type Approval System. This certificate is issued to: PRODUCER DESCRIPTION TYPES APPLICATION RATINGS Krone Filter Solutions GmbH Industriestrasse 19 28876 Oyten Germany Single, duplex and self-cleaning automatic filter with several housing sizes and combinations made from standard materials spheroidal iron castings EN-GJS-500-7 (GGG 50)* or EN-GJS-400-15 (GGG 40), carbon steel...

Open the catalog to page 5All Sterner AS catalogs and technical brochures

-

OxyGuard Handy Salinity

2 Pages

-

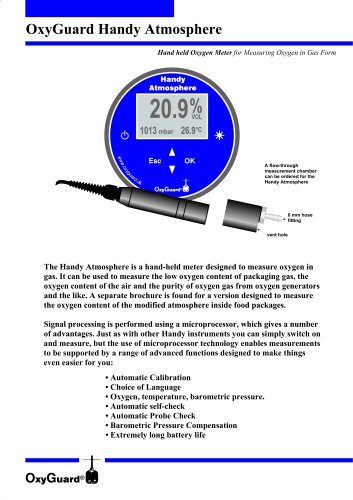

OxyGuard Handy Atmosphère

2 Pages

-

OxyGuard Polaris 2 TGP

2 Pages

-

OxyGuard Polaris 2 TGP

2 Pages

-

OxyGuard CO2 Portable

2 Pages

-

NESTE GENERASJON CO2-LUFTER

2 Pages

-

NP Innovation

3 Pages

-

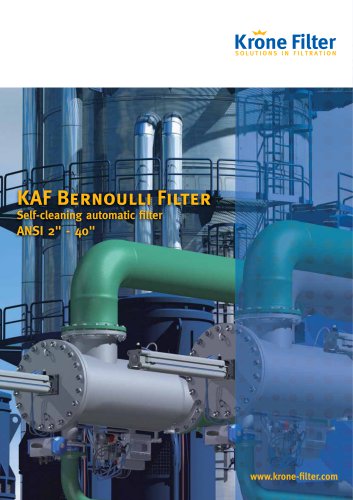

KAF Bernoulli Filter

8 Pages

-

KAF Bernoulli

4 Pages

-

SMOevo Ozone Systems

4 Pages

-

SMOevo Ozone Systems

8 Pages

-

WEDECO GSO Series

2 Pages

-

Spektron UV Series

8 Pages

-

Quadron UV series

8 Pages

-

Duron UV System

8 Pages

-

AquaZone

8 Pages

-

Complete systems Aquaculture

5 Pages