Catalog excerpts

2 tapered roller bearings to absorb the axial forces Mechanical seal SiC/SiC independent of rotation direction Interim bearings for the drive shaft (slide bearings) with both sided polygonal slip-on connection Tube length 4.0 / 5.0 / 5.5 m Tube 0 159 x 5 mm, ss304 Sealing plate 120 x 120 cm (143 x 143), ss304 ss316 on request Sealing membranes of EPDM60 Installation up to 8 m below subtrate level, other immersion depths on request 3 liter oil inspection glass for monitoring the tightness Agitator completely manufactured in modular design Power take-off with protection for tractor operation POM protection to minimize abrasion Propeller 3-biade high efficiency propeller, dynamically balanced ss304, optional ss316 or hardend steel Lateral adjustment ± 30° through handspindle Tilt adjustment up to ± 30° through hydraulic cylinder Tank openings: 800 x 800 mm (plate 120 cm) Ex-Zone Ex-zone 2 (outside the tank) up to the PTO of the agitator and Ex-zone 1 (inside the tank) Classification mechanical components: C E II 2G Ex h IIA T1 Gb INDUSTRY BIOGAS

Open the catalog to page 1

Subject to technical changes * Calculated via CFD simulation and validated in test basin with water © SUMA Ruhrtechnik GmbH | Martinszeller Str. 21 | DE-87477 Sulzberg Phone: +49 8376 / 92131 - 0 | Fax: - 19 | info@suma.de | www.suma.de/en INDUSTRY BIOGAS

Open the catalog to page 2All SUMA Rührtechnik catalogs and technical brochures

-

2023 Agitators & Pump for biogas

36 Pages

-

OPTIMIX 2G

2 Pages

-

OPTIMIX 3G 250-270

2 Pages

-

GIANTMIX AMX

2 Pages

-

REKORDMIX B1

2 Pages

-

OPTIMIX 2G 150-275

2 Pages

-

SUMA Pump Pressura TP

2 Pages

-

SUMA Pump Pressura LW

2 Pages

-

SUMA MGD

1 Pages

-

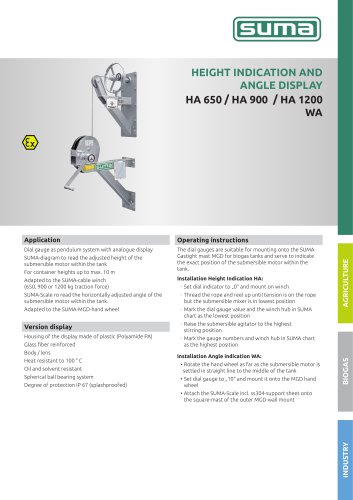

SUMA Height indication

2 Pages

-

SUMA EV3 light

1 Pages

-

SUMA GDD

2 Pages

-

SUMA Giantmix Z5 stationary

2 Pages

-

SUMA Giantmix Z5

2 Pages

-

SUMA Giantmix Z4

2 Pages

-

SUMA Giantmix FT HY

2 Pages

-

SUMA Giantmix FR HY SP

2 Pages

-

SUMA Giantmix FR HY 30

2 Pages

-

SUMA Giantmix Z-MIX

4 Pages

-

SUMA Giantmix S-MIX

2 Pages

-

SUMA Giantmix FTX Top

2 Pages

-

SUMA Giantmix FTX

2 Pages

-

SUMA Giantmix FT stationary

2 Pages

-

SUMA Giantmix FT Top

2 Pages

-

SUMA Giantmix FR light

2 Pages

-

SUMA Giantmix FR Steeltower

2 Pages

-

SUMA Giantmix FR Top

2 Pages

-

SUMA Giantmix BG2 Top

2 Pages

-

SUMA Giantmix AMX Top

2 Pages

-

SUMA Giantmix AMT SL

2 Pages

-

SUMA Giantmix AMT LL

2 Pages

-

SUMA Optimix adjustable

2 Pages

-

SUMA Optimix ECO mobil

2 Pages

-

SUMA Optimix 4G

2 Pages

-

SUMA Optimix 3G 25kW

2 Pages

-

SUMA Optimix 3G 10kW

2 Pages

-

SUMA Optimix 3A

2 Pages

-

SUMA Optimix 2G stationär

2 Pages

-

SUMA Optimix 2G 185-275

2 Pages

-

SUMA Optimix 2G 75-380

2 Pages

-

SUMA Optimix 2G mobil

2 Pages

-

SUMA Optimix 2G 90-75

2 Pages

-

SUMA Optimix 2A 15kW

2 Pages

-

SUMA Optimix 2A 13,5 kW

2 Pages

-

SUMA Optimix 2A 9kW

2 Pages

-

SUMA Optimix 2A 4kW 950 rpm

2 Pages

-

SUMA Optimix 2A 720 rpm

2 Pages

-

SUMA Optimix 2A 4kW

2 Pages

-

Giantmix MZR Lagoon

2 Pages

-

Giantmix MZR

2 Pages

-

Giantmix Z5

2 Pages

-

Giantmix Z3

2 Pages

-

Rekordmix

2 Pages

-

Giantmix BG2

2 Pages

-

Giantmix FR stationary

2 Pages

-

Giantmix Z3 HY stationary

2 Pages

-

Agitators & Pumpsfor agriculture

40 Pages

-

INDUSTRIAL AGITATORS

12 Pages

-

GIANTMIX FR SP

2 Pages

-

GIANTMIX FR 30°

2 Pages

-

GIANTMIX FT

2 Pages

-

GIANTMIX Z6

2 Pages

-

OPTIMIX2G 150-275

2 Pages