Website:

Sumo UK Ltd.

Website:

Sumo UK Ltd.

Catalog excerpts

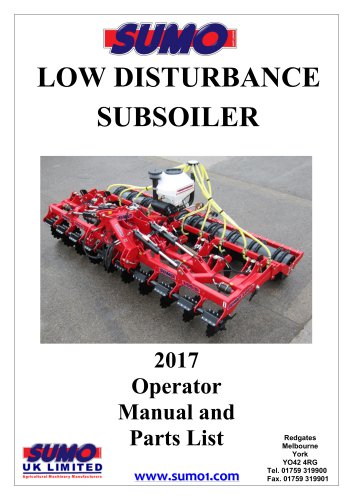

2017 Operator Manual and Parts List www.sumo1.com

Open the catalog to page 1

To activate your SUMO Warranty, you must complete this page and send it back to us at: Sumo UK Ltd Redgates Melbourne York YO42 4RG Tel. 01759 319900 Fax. 01759 319901 (NO REGISTRATION = NO WARRANTY) SUMO SERIAL No: For your own records. (Serial plate on side of headstock) LDS Registration Document NAME: ADDRESS: Postcode: Telephone Number: DATE: SUMO SERIAL No. (Serial plate on side of headstock) DEALERSHIP NAME AND BRANCH:

Open the catalog to page 3

In order to obtain your free pair of Sumo overalls and baseball cap please fill in this form and send back to us at: Sumo UK Ltd Redgates Melbourne York YO42 4RG Tel. 01759 319900 Fax. 01759 319901 Overall size: tick where applicable Small (38 chest) Medium (42 chest) Large (46 chest) Extra large (50 chest) XX Large (54 chest) XXX Large (58 chest)

Open the catalog to page 4

2.0 Summary The SUMO Low Disturbance Subsoiler has been developed to alleviate compaction in the subsurface region of most soil types. The design of the LDS enables this lift and fracture to be carried out whilst creating minimal surface disturbance. When used in conjunction with the Sumoseeder the LDS becomes an effective tool for the establishment of OSR and other small seed crops. Firstly A leading row of straight serrated discs cut through any surface trash eliminating any build up around the following subsoiler legs. The discs have adjustable depth positions which are easily altered...

Open the catalog to page 5

Table of Contents 1.0 Registration 2.0 Summary 3.0 Safety 3.1 Qualification and Training 3.2 General Safety 3.3 Special Safety Instructions 3.4 Risk Assessment 4.0 Operation and Adjustment 4.1 Operation 4.2 Adjustments 4.3 Auto Reset Legs 5.0 Maintenance 5.1 Spares 5.2 Winter Storage 6.0 Parts and Assembly 6.1 Single Disc Unit 6.2 Front Disc Angle Adjustment 6.3 Packer Assembly 6.4 Packer Depth Assembly 6.5 Scraper Assembly 6.5.1 Flat Roller Scraper 6.5.2 Ringed Roller Scraper 6.5.3 Double Ringed Roller Scraper 6.6 Auto Reset Assembly 6.7 Leg and Point Assembly 6.8 Arable Leg Assembly 6.9...

Open the catalog to page 6

3.0 Safety This manual contains basic advice which should be observed during setting-up, operation and maintenance. Therefore, this operating manual must be read by the personnel concerned prior to starting up, using the machine and be available at all times. If safety instructions are not complied with, then this can lead to the risk of injury to yourself and others as well as damage to the environment or the machine. Non-compliance to the safety instructions can also lead to claims for damages becoming invalid. 3.1 Qualification and Training Ensure that only reliable, authorized...

Open the catalog to page 7

3.2 General safety Warning signs and other notices on the machine provide important information for the safe operation. Observing them will serve your safety. Before starting work, make yourself familiar with all the equipment and controls as well as their functions. The user should wear close-fitting clothing. Keep the machine and in particular the bearings clean to avoid risk of fire. Check around the machine before moving off or starting up (watch out for children!). Make sure you have adequate all-round visibility. Always match your speed to the local conditions. Avoid...

Open the catalog to page 8

Date assessment written: 3.4 RISK ASSESSMENT Purpose of machine: Ensure the operator manual is read and fully understood. Primarily designed to alleviate compaction and improve soil structure with minimal surface disturbance. A three-point-linkage mounted farm implement consisting of 3 major elements. 1. A row of rubber suspended, straight, notched discs. 2. A bank of staggered low disturbance subsoiler legs. 3. A toothed roller, optionally followed by a scarifying harrow. All of the above is arranged in a heavy duty fabricated steel framework. The Machine is designed to couple to a...

Open the catalog to page 9

4.0 Operation and Adjustment 4.1 Operation Before attaching the Low Disturbance Subsoiler to a tractor is essential that the stands are in the down position to ensure a short top link once attached. Once attached securely to the tractor the machine can then be raised and the stands lifted out of the way. When the machine is removed from the tractor it is equally as important to leave the machine on the stands. Due to the physical nature and weight distribution of the Sumo LDS a category three enclosed ball top link is highly recommended as the best option for dealing with the exaggerated...

Open the catalog to page 10

4.3 Auto Reset hydraulic circuit 1) To lift the legs up and out of the work position; pressurize line B (the lower of the two hoses entering the valve block & marked “B” on the valve itself). The legs will lift as oil is returned to the tractor through Line A. 2) To lower the legs back down and into the work position; pressurize line A, the legs will lower one by one. Keep pumping until all of the legs come to a stop at the end of their stroke. Keep pumping for a few more seconds and the two lines will then pressure up. Keep an eye on the gauge on the right hand side of the machine as this...

Open the catalog to page 11

5.0 Maintenance The packer bearings should be greased with one pump once a week and after washing off. The disc bearings should be greased until old grease is forced out once a week when in normal use and after washing off. The condition of the subsoiler legs, the points and the discs should be regularly monitored in order to maintain the most efficient use of the machine. The condition and position of the packer scrapers should also be observed in order to prevent soil building up on the packer. Ensure the scrapers are not touching the packer though, as this will add rolling resistance as...

Open the catalog to page 12

6.1 Single Disc Unit DO NOT SCALE DRAWING MACHINE/COMPONENT: Single Disc Unit Drawings and design information found herein remain the sole property of Sumo UK Ltd. Reproductions may only be made with the permission of the owner.

Open the catalog to page 13

6.2 Front Disc Angle Adjustment DO NOT SCALE DRAWING MACHINE/COMPONENT: Front Disc Angle Arm M16 x 50 Bolt M16 Washer M16 Nylock Nut 3m Front Disc Bar Front Disc Angle Adjustment Drawings and design information found herein remain the sole property of Sumo UK Ltd. Reproductions may only be made with the permission of the owner. SCALE 1:5

Open the catalog to page 14All Sumo UK Ltd. catalogs and technical brochures

-

Multipacka Front Press

20 Pages

-

STRAKE

34 Pages

-

DTS & DD DRILL Operator Manual

48 Pages