Catalog excerpts

TimberPro BS-32 Bar Saw Operation, Maintenance, and Parts Operation, Maintenance, and Parts

Open the catalog to page 1

Introduction ... Dear Valued Customer, This catalog contains operating instructions, maintenance instructions and parts information for the TimberPro 32” Bar Saw attachment, including normally available options. Although great care was employed during the preparation of this manual to insure the accuracy of illustrations and listings, TimberPro Inc, cannot be held responsible for errors or substitutions, nor changes made after the date of issue. This catalog is compiled from information available and current at the time of documentation, TimberPro Inc, reserves the right to improve it’s...

Open the catalog to page 2

Table Of Contents ... Group 1 - Operator and Maintence Information Critical Operator Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Service And Maintenance Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cutting Attachment Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bar Saw Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Saw Chain Maintenance ....

Open the catalog to page 3

CRITICAL INFORMATION THE OPERATOR SHOULD UNDERSTAND BEFORE OPERATING THE BAR SAW 1. THE CHAIN MUST BE SHARP WITH RAKERS SET AT SUGGESTED HEIGHT. a) A dull chain will bring out powder instead of long worm-like chips, and besides cutting slowly, will cause heat and prematurely wear out the bar. b) A bent guide link will also cause heat through additional friction and cause premature bar wear. 2. THERE MUST BE ADEQUATE CHAIN LUBE. a) Because this is so critical to prolong bar life, the operator needs to constantly monitor the bar oil resivoir level and proper function of the bar oiler system....

Open the catalog to page 4

General Safety Information TimberPro’s policy is to produce products that are safe and reliable. However, even when using well engineered equipment, there will always be an element of risk in heavy equipment operation. Most accidents involving heavy equipment operation, maintenance or service result from failure to follow basic safety rules and precautions. Study all the safety messages carefully, remember them and apply them when operating, maintaining or servicing equipment. Identifies that a safety hazard exists. Failure to follow a WARNING safety message can result in death or serious...

Open the catalog to page 5

Comply with the instructions in this manual and your company’s regulations for the operation of this machine. Use recommended protective clothing and safety devices such as gloves, safety boots, safety hat, reflective vests and eye, ear and respiratory protection as required by job conditions. YOU MUST BE FULLY TRAINED to operate this machine and its attachments. General Unless otherwise specified, all maintenance or repair procedures should begin as follows: 1) Position machine on level ground. 2) Lower boom and all attachments to the ground. 3) Shut down engine. Remove ignition key and...

Open the catalog to page 6

Keep all fuels and maintenance items in properly marked containers. Place all fuel or oil soaked rags, waste material, debris and other flammable items in a properly marked protective container stored in a safe place. Inspect the machine for missing, unreadable or damaged safety decals. Keep safety decals clean. 00019 Before performing maintenance or repairs on the machine, consult this manual and follow the recommended procedures. Run the engine only when it is required for test or adjustment purposes.Always use the proper tools for the job. Repair or replace any broken or damaged tools,...

Open the catalog to page 7

Cutting Attachment Safety Information Pressure can be maintained in system circuits long after the engine and pumps have been shut down. Release trapped pressure in hydraulic, fuel, and cooling system lines before performing any maintenance or repair procedures. Hydraulic System - Always follow the attachment manufacturer’s operating instructions: Do not bend or install bent or damaged hydraulic hoses and tubelines. – Never use the saw so that the saw bar or disc saw is directly in line with the cab or other persons. Do not strike hydraulic hoses or tubelines. – Ensure chain speed does not...

Open the catalog to page 8

General Bar Saw Maintenance Information every 50 hours. When greasing the tilt bearing be carefull not to over-grease and damage the main seal. Checking the proper operaton of the saw chain oiler can be done by operating the saw and monitoring the end of the bar. A visual mist coming from the end of the saw bar will indicate the bar is recieving oil. (See "Saw Chain Oiler Operation" for description and operation of the saw chain oiler.) If the oil is too cold or thick to gravity feed into the oiler, or a check valve is not working properly, the saw chain oiler will not operate. Before...

Open the catalog to page 9

Saw Chain Oiler Operation The TimberPro bar saw is equipped with a lubrication oil pump integrated with the feed out cylinder. The lubrication oil pump supplies oil via a piston operation to the saw chain during the entire feed out process.The lubrication oil pump is fed with oil from the oil tank (1), through the inlet check valve (2) and to a reservoir in the piston rod (3).When the saw bar (8) is fed out, the oil goes through the outlet check valve (4), via a hydraulic hose (5) to the swivel in the saw motor (6) and finally through the bar holder to the saw bar (8). Make sure that the...

Open the catalog to page 10

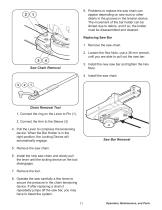

9. Problems to replace the saw chain can appear depending on saw dust or other debris in the grooves in the tension device. The movement of the bar holder can be limited due to debris, and if so, the holder must be disassembled and cleaned. Replacing Saw Bar 1. Remove the saw chain. 2. Loosen the Hex Nuts, use a 36 mm wrench, until you are able to pull out the saw bar. 3. Install the new saw bar and tighten the Hex Nuts. Chain Removal Tool 1. Connect the ring on the Lever to Pin (1). 2. Connect the Arm to the Sleeve (3) 4. Pull the Lever to compress the tensioning device. When the Bar...

Open the catalog to page 11All Timberpro catalogs and technical brochures

-

Disc Saw Manual

44 Pages