Catalog excerpts

ROTARY SCREENS STATIC SCREENS

Open the catalog to page 1

Process Description Rotary screens are pretreatment equipment used to separate solid waste from clean water through a filter drum. This drum can be either screen or perforated depending on the type of solids to be treated. We have developed an intelligent programme for our screens. They detect the amount of solids accumulation and only rotate when necessary. In addition, this programme allows you to control the sieve records through an app on your mobile phone. (Optional) These are independent units with self-cleaning systems and automatic operation. TR SMART ® NEW SMART PROGRAMME We have...

Open the catalog to page 2

Process Description | Rotary Screens SIMPLE OPERATION • The effluent to be treated enters through the flange on the outside of the screen body and is evenly distributed through the spillway and overflow through the filtering drum. • The solids are retained on the surface of the drum while it is rotating, the spillage penetrates through the mesh aperture and performs a self-cleaning function by passing through the lower part of the drum again. • As it passes through the outer scraper, the solids are released from the screen and gravity causes the solids to fall off the scraper. Unscreened...

Open the catalog to page 3

Rotatory Screen | Models ROTARY SCREENS CAPACITY • Small flow rates. • Produces polished effect, high output water quality. • High performance with high solids load. • Protected from outlet overloads. • Smaller filter surface. • Solid, non-collapsing, high-strength infused GRP lamella construction. Easy to clean • From 30 m3/h to 228 m3/h in clean water. HIGH PRESSURIZATION SYSTEM SCREENS CAPACITY • From 133m³/h up to 5.874m³/h. • High volumes in less space. • Increased screening capacity for fine particles. DESCRIPTION • Capable of handling four times the volume of a conventional screen. •...

Open the catalog to page 4

Manufacturing MANUFACTURING • Safe designs with high quality materials • GRP flanges with DIN/ANSI connection. • Manufactured in 316 L stainless steel. • Pressurised water cleaning system for the filtering drum. • Shot blasted finish. • Incorporates effective safety system. • Solids scraper adjustment FILTER DRUM CLEANING SYSTEM DRIVE UNIT

Open the catalog to page 5

Tipos de mallas | Fabricación In our factory in Villavaquerín we manufacture different models of floats which, together with the different sizes of flocculators and pressurisation skid, allow us to adapt to the needs of the client depending on the flow and load of solids to be treated. MESH GRID Mesh size from 2 to 3 mm Ø PERFORATED MESH Scales - Gelatinous bodies Film, plastics... Long fibres - e.g. hair, bristles... Fats* MSS Sands Weed Wash * With pigs cleaning of meshes at water temperature < 50º. Recommended

Open the catalog to page 6

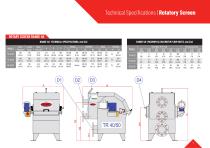

Technical Specifications | Rotatory Screen ROTARY SCREEN RANGE 40 RANGE 40- TECHNICAL SPECIFICATIONS, mm (in) MODEL Drum Diameter Length Drum RANGE 40- MAXIMUM CLEAN WATER FLOW RATES, mm (in) Perforated mesh

Open the catalog to page 7

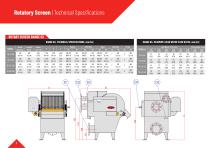

Rotatory Screen | Technical Specifications ROTARY SCREEN RANGE 63 RANGE 63- TECHNICAL SPECIFICATIONS, mm (in) MODEL Drum Diameter Length Drum RANGE 63- MAXIMUM CLEAN WATER FLOW RATES, mm (in) Input Perforated mesh

Open the catalog to page 8

HPS SIEVE RANGES M/L TP HPS- TECHNICAL SPECIFICATIONS, mm (in) MODEL Drum Diameter Length Drum TR HPS- MAXIMUM CLEAN WATER FLOW RATES, mm (in) D3 Perforated mesh

Open the catalog to page 9

Rotatory Screen | Optionals EQUIPAMIENTO BODY Material AISI 304 Threaded connections Protective cover Double/triple inlet flange 3" inlet chamber drain Protective motor casing Flow inlet baffle DOCUMENTATION Operating manuals in specific languages ISO standard documentation ∙ Standard equipment ∙ Optional equipment 40 NOTES: - Optional equipment may have an extra cost on the product. Please consult our technical department. - Standard and optional equipment may vary slightly due to normal product development by Toro Equipment, S.L. technical team. - When placing your order, please ask for...

Open the catalog to page 10

Opcionals | Rotatory Screen EQUIPMENT ELECTRICAL PANEL Integration of electrical panel Start/stop Automatic programming of the cleaning system Safety limit switch protection cover Protective cover support bracket Emergency stop ∙ Standard equipment ∙ Optional equipment 40 • The electrical panel includes as standard, Start/Stop, limit switch to stop the drum when the safety cover is lifted, safety cover support, emergency stop and automatic programming of the cleaning system. • Start/Stop, start/stop of the machine in the presence or absence of flow. Level detection device that activates the...

Open the catalog to page 11

Static Screens | Description The Defender® Static Sieves are pre-treatment equipment for refining the process of solid-liquid waste elimination through a mesh screen of different calibre depending on the type and quantity of solids to be treated, which filters the water from the solids. Its mission is to eliminate the solids carried by the water, in order to avoid clogging and mechanical problems in the installations. They are equipment with little maintenance service and their operation is continuous, without the need for electrical current. In urban waters, they can replace primary...

Open the catalog to page 12

Process Description | Static Screens SIMPLE OPERATION • The effluent to be treated is pumped or pressurised to the screen head. Unscreened water intake • After a certain retention time, determined by the filling of the sieve feed box, a laminar overflow occurs, in which the liquid slides smoothly through the filter mesh. • In this sliding process, the liquid passes through the mesh (most of it in its first section), with the solids retained on the surface of the mesh and falling towards the bottom, draining out of the screen. The filtered liquid falls into the lower tank and is evacuated by...

Open the catalog to page 13

Static Screens | Technical Specifications APPLICATIONS TE static screens have countless applications in the pretreatment of wastewater for practically all types of industries. The performance is optimal in those applications in which there are no greases, obtaining with this system greater dryness than even with rototamices.En industria alimentaria en general. TE- TECHNICAL SPECIFICATIONS, mm (in) MODEL • Coarse screening after roughing screen in urban water treatment. • Recirculation of water in cleaning circuits. • Tank washers • Screening of water from the plastics, paper and wood...

Open the catalog to page 14All Toro Equipment catalogs and technical brochures

-

Filter-press_Draco_web

12 Pages