Catalog excerpts

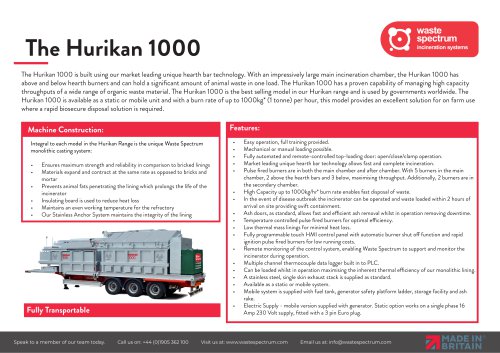

The Hurikan 1000 The Hurikan 1000 is built using our market leading unique hearth bar technology. With an impressively large main incineration chamber, the Hurikan 1000 has above and below hearth burners and can hold a significant amount of animal waste in one load. The Hurikan 1000 has a proven capability of managing high capacity throughputs of a wide range of organic waste material. The Hurikan 1000 is the best selling model in our Hurikan range and is used by governments worldwide. The Hurikan 1000 is available as a static or mobile unit and with a burn rate of up to 1000kg* (1 tonne) per hour, this model provides an excellent solution for on farm use where a rapid biosecure disposal solution is required. Machine Construction: Integral to each model in the Hurikan Range is the unique Waste Spectrum monolithic casting system: • • • • • • Ensures maximum strength and reliability in comparison to bricked linings Materials expand and contract at the same rate as opposed to bricks and mortar Prevents animal fats penetrating the lining which prolongs the life of the incinerator Insulating board is used to reduce heat loss Maintains an even working temperature for the refractory Our Stainless Anchor System maintains the integrity of the lining Fully Transportable Speak to a member of our team today. Easy operation, full training provided. Mechanical or manual loading possible. Fully automated and remote-controlled top-loading door: open/close/clamp operation. Market leading unique hearth bar technology allows fast and complete incineration. Pulse fired burners are in both the main chamber and after chamber. With 5 burners in the main chamber, 2 above the hearth bars and 3 below, maximising throughput. Additionally, 2 burners are in the secondary chamber. High Capacity up to 1000kg/hr* burn rate enables fast disposal of waste. In the event of disease outbreak the incinerator can be operated and waste loaded within 2 hours of arrival on site providing swift containment. Ash doors, as standard, allows fast and efficient ash removal whilst in operation removing downtime. Temperature controlled pulse fired burners for optimal efficiency. Low thermal mass linings for minimal heat loss. Fully programmable touch HMI control panel with automatic burner shut off function and rapid ignition pulse fired burners for low running costs. Remote monitoring of the control system, enabling Waste Spectrum to support and monitor the incinerator during operation. Multiple channel thermocouple data logger built in to PLC. Can be loaded whilst in operation maximising the inherent thermal efficiency of our monolithic lining. A stainless steel, single skin exhaust stack is supplied as standard. Available as a static or mobile system. Mobile system is supplied with fuel tank, generator safety platform ladder, storage facility and ash rake. Electric Supply - mobile version supplied with generator. Static option works on a single phase 16 Amp 230 Volt supply, fitted with a 3 pin Euro plug.

Open the catalog to page 1

waste spectrum incineration systems Specification - Metric Burn Rate Operational Dimensions (LxWxH) External Height External Height Mobile Weight Chamber Actual Volume Chamber Load Volume Chamber Load Capacity Burner Output Fuel Consumption Fuel Consumption Fuel Consumption Specification - Imperial Up to Ibs/hr Feet ft inc. stack ft ex. stack Ibs Ibs ft3 ft3 Ibs Btu Diesel US GPH LPG US GPH Nat Gas ft3/h Ideally Suited For: A wide range of animal carcasses Abattoir waste Emergency response High capacity Custom Built Solutions: Custom Built Solutions Available All specifications are based on...

Open the catalog to page 2All Waste Spectrum Incineration Systems catalogs and technical brochures

-

The Hurikan 300

2 Pages

-

The Volkan 1750

2 Pages

-

The Volkan 750

2 Pages

-

The Volkan 2000 G

2 Pages

-

The Hurikan 500

2 Pages

-

The Hurikan 150 M

2 Pages

-

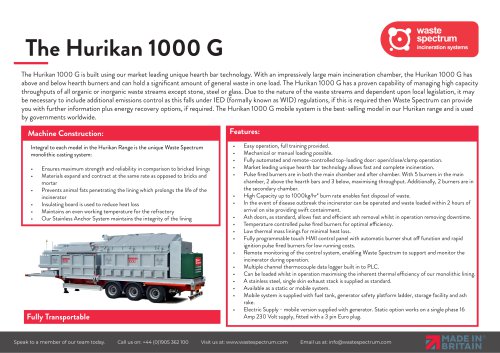

The Hurikan 1000 G

2 Pages

-

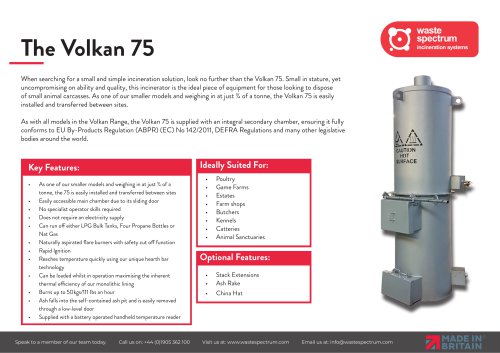

The Volkan 75

2 Pages

-

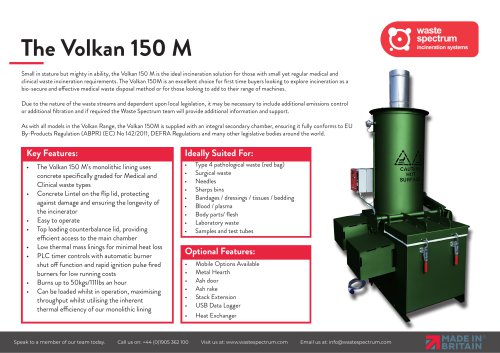

The Volkan 150 M

2 Pages

-

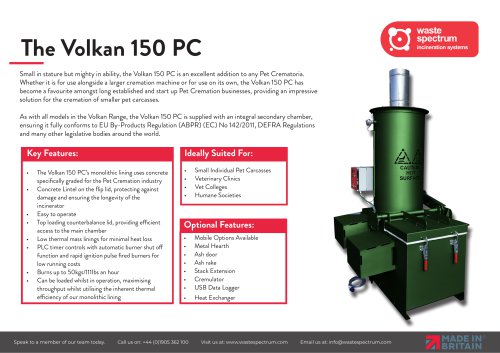

The Volkan 150 PC

2 Pages

-

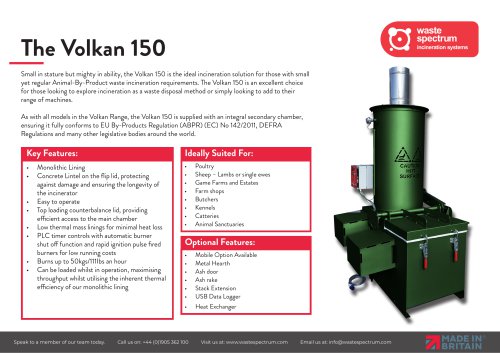

The Volkan 150

2 Pages

-

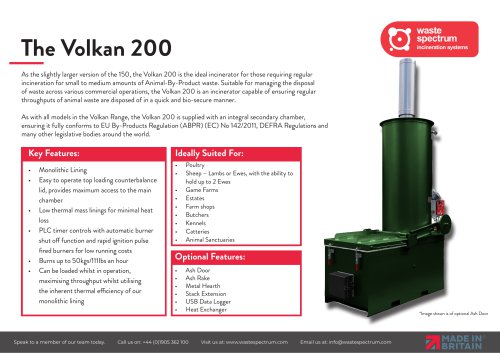

The Volkan 200

2 Pages

-

The Volkan 500 M

2 Pages

-

The Volkan 500 PC

2 Pages

-

The Volkan 500

2 Pages

-

The Volkan 400

2 Pages