Catalog excerpts

Contents Page Installation of load cells and amplifier 3 & 4 Commissioning the silo weigher 7 Auto detection of deliveries 8 Silo weights and statistics 9 Remote data collection 9 Silo amplifier diagram 13

Open the catalog to page 1

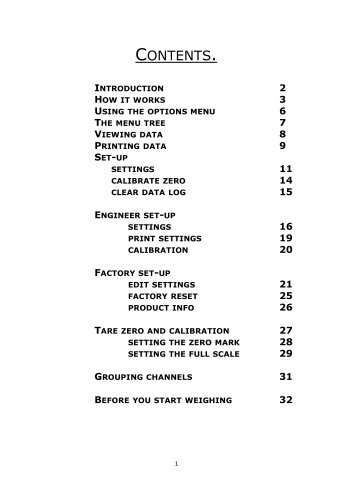

1. SHOW DATA 2. SILO STATUS 3. TARE MENU 4. PRINT REPORT 5. SETUP 1. SETTINGS 2. CALIBRATE ZERO 3. CALIBRATE SILO 4. LOCK THE MENU 5. CLEAR DATA LOG 6. ENGINEERS SETUP 1. ALL REPORTS 2. SUMMARY REPORT 3. INVENTORY 4. LAST DELIVERY 5. HISTORY REPORT 6. SW8001b REPORT 7. ALARM SETTINGS 1. CLEAR DEL. TODAY 2. CLEAR USED DATA 3. CLEAR ALL HISTORY 1. CONFIGURE 2. PRINT SETTINGS 3. TEST ALARM 4. PRODUCT INFO 5. FACTORY RESET 6. ANALOGUE VIEW 7. VIEW CHARSET 8. SET SCALING 9. CLEAR CELL FAULT 1. TARE ON/OFF 2. SET TARE MARK 3. QUIT TIME NOW TODAYS DATE LOW ALARM HIGH ALARM MIDNIGHT PRINT JOURNAL...

Open the catalog to page 2

INSTALLATION OF LOAD CELLS AND AMPLIFIER A standard silo weighing system will have two or four load cells and one amplifier for each silo being weighed. The first procedure after unpacking is to install the load cells as follows: 1. Make sure that the silo is empty and all power to augers etc. is disconnected. This will ensure that no one can inadvertently switch them on and cause vibration when the silo legs are being cut, or the load cells are being fitted. Safety procedures must be observed at all times. Do not attempt to fit load cells in adverse weather conditions. The silo will be...

Open the catalog to page 3

Insert the load cell assembly and tack weld the top shoe to the silo leg, care must be taken not to heat the load cell as this can cause irreparable damage. Remove the load cell and complete the weld to the leg. Remove the foot from the bottom of the cut off section of the silo leg, drill leg as required and refit foot to the bottom of the leg. Slide shoe assembly under leg and bolt to the newly fitted foot. Using Raw bolts or similar bolt the foot to the concrete base. Repeat steps four to six on the remaining three legs. The amplifier is supplied in a weather proof box with a connection...

Open the catalog to page 4

Overview of SW8011 weigher. The SW8011 is a unit that can display the contents of up to 10 silos, this information can be accessed at will via the screen or it can be sent to a computer or printer. Functional description. The unit monitors the weight of up to 10 feed silos. Silo weights are recorded and logged to memory. At midnight each day the data can be printed it is also archived and cleared for the next day. Data may also be printed or viewed on demand. A PC may be connected (directly or via a modem) to interrogate the unit. Silo weights may be extracted using the Windows Datapol...

Open the catalog to page 5

Tare setting. The tare setting allows the operator to set a temporary mark of the weight. For example he might want to discharge 1000 kg. He can set the tare mark and a negative tare, so that the display will show the weight discharged. When tared, the display announces 'TARE' instead of the usual 'SILO' heading. After one hour, the tare mode is cancelled and the display reverts to showing the actual weight. However the tare weight mark is remembered for later use until reset by the operator. This tare setting is distinct from the Calibrate Zero setting used when a silo is empty. Alarms. An...

Open the catalog to page 6

Commissioning the silo weigher. When first turned on, a factory reset is required and this leaves all silos disabled. The display will say ‘OUT OF SERVICE’ and shows uncalibrated weights. You can turn on a silo manually with the Engineer setting ‘Feed program’. It is also enabled automatically when you are calibrating the silo. Each silo is commissioned by the following steps in order, kept brief for clarity: 1. Begin with an empty silo. 2. Enter the low and high alarm settings from the Setup menu. A low alarm set to 0 disables the low weight alarm. 3. Select 'Calibrate zero' from the Setup...

Open the catalog to page 7

Calibrate silo. The Silo Calibration sets the scale or ratio of the load cell input. When the silo contains feed, you can calibrate it by dialling in its contents weight. The voltage input must be more than a quarter way up the voltage range, and the operation takes account of the zero point previously set (see Calibrate zero). If the amplifier gain changes after calibrating, the scaling factors become invalid. After calibrating the silo with a load of feed, you get asked whether to set up a new datalog using this weight as the first delivery. You can rescale the silo at any time, or repeat...

Open the catalog to page 8

Silo weights and statistics. The unit has 2 recording functions: a) it records the silo weights at midnight. b) it detects deliveries from the weight rise. The feed used is calculated by dead reckoning from the midnight weight, current weight and any delivery. The average feed used is calculated over the last 7 days from the midnight weight history. The average excludes today, so will not change during its course - unless this is the first day of use. Remote data collection. The weigher will communicate with Datapol version 3.20 which will collect the weight information and maintain data...

Open the catalog to page 9

Select the SETTINGS menu item.

Open the catalog to page 10

The following commands (examples for unit 1) are accepted at the modem port: send id string send serial number set the keyboard pin unlock the setup menu cancel the alarm output cancel the alarm output and send alarm statuses disable midnight printout enable midnight printout disable printer journal enable printer journal send list of process control settings set process control for silo c (1..) or All to 0 or 1 send list of logged dates send the date ddmmyy set the date ddmmyy send the time hhmm set the time hhmm send the farm name set the farm name to ffffff send the farm address set the...

Open the catalog to page 11

Program flash Datalog and RAM Silos Weight units Max weight Daily history Max baud rate Printer width Handshake timeout Input range 256k 128k 10 Kgs or Lbs 64000 Kgs or Lbs 8 days (including today) 19200 bps (possibly up to 115200) 24 characters 500 milliseconds 0 - 2.4 volts

Open the catalog to page 12

CELL OUTPUT YELLOW CELL OUTPUT GREEN ULTRA FINE ZERO POT ZERO SWITCHES SPAN SWITCHES SPAN FINE SETTING POT SILO AMPLIFIER POWER GROUND ANOLOGUE GROUND +12 VOLTS FROM CONTROL -12 VOLTS FROM CONTROL

Open the catalog to page 13All Weltech International Limited catalogs and technical brochures

-

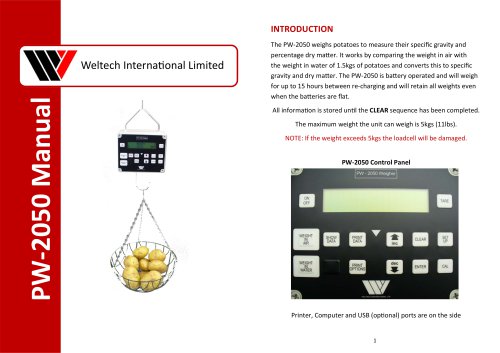

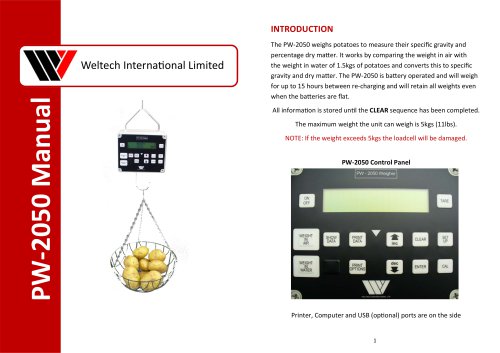

PW-2050

8 Pages

-

BW-2050 Small Kit

11 Pages

-

BW-2050 Full Kit

11 Pages

-

BW-8010 Kit

33 Pages

-

PW‐2050

8 Pages