Catalog excerpts

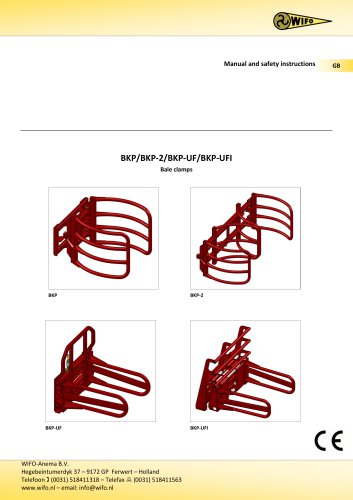

Manual and safety instructions WIFO-Anema B.V. Hegebeintumerdyk 37 – 9172 GP Ferwert – Holland Telefoon (0031) 518411318 – Telefax (0031) 518411563 www.wifo.nl – email: info@wifo.nl

Open the catalog to page 1

The aim of this manual is to inform users about the commissioning, use and maintenance of their new WIFO stationary box rotator. Also included in this manual are a number of safety instructions to create a safe working environment. At WIFO-Anema B.V. we aim to continuously improve our products. WIFO-Anema B.V. reserve the right to introduce any changes and improvements deemed necessary without prior notice. Please read the manual thoroughly and observe the safety procedures before putting the unit into operation. Contact your dealer for any further questions or concerns you may have. We...

Open the catalog to page 4

1.2 Safety precautions and warnings Please read this manual before you put the machine into operation for the first time, and observe the safety instructions at all times. The most important instructions are marked with a symbol. Any person in charge of the commencement of operation, the operation itself or the maintenance of the machine is urged to carefully read and observe the following instructions. Adjust the height setting to the correct height. This must be 2 cm greater than the total box height. Fix the adjusting bar at the correct level. For transportation using the K60/K60-AKB,...

Open the catalog to page 5

Persons must not stand below the box, and must remain outside the working range of the box rotator. Bear in mind that items may fall from the box. Only sound boxes must be used for tipping operations. Load boxes in such a way that the load can not fall unexpectedly or be damaged. Ensure that there is adequate visibility of the work activities from the operating position. Make sure the hydraulic hoses and any power cables do not get jammed and that the box rotator is able to move freely. The generator oil level must be periodically checked. The oil temperature must not exceed 80°C....

Open the catalog to page 6

Safety stickers and warning signs A safe working environment also requires personnel to be well-informed about the various safety stickers on the machine. Be aware of the hazards they warn you to look out for. Replace any loose, illegible or missing stickers. Several safety stickers have been put onto the machine. The meaning of the stickers on this machine is as follows: N.B.: Please read the instructions from the manual prior to any maintenance to the machine. Turn off the engine and remove the key from the ignition while maintenance is carried out on the machine! Danger: Always keep at a...

Open the catalog to page 7

The WIFO stationary box rotator is suitable solely for the purpose of rotating boxes to the rear, provided the total weight of the box and its load does not exceed 2000kg.

Open the catalog to page 8

Liability 1. Work must be carried out in accordance with the directions and within the functional restrictions (e.g. maximum hydraulic working pressure) as outlined in the regulations. Use only sound and appropriate tools. 2. Electric/electronic equipment and accessories (e.g. cables) must be treated in accordance with the general accepted policy for using non-waterproof portable electric and electronic equipment, such as: a) Storing and keeping in a clean, dry environment away from rodents and the like; and b) Protecting the equipment against severe, uncushioned shocks and water...

Open the catalog to page 9

Table 2.1.3-Information on hydraulic generator

Open the catalog to page 10

2.2.1 Parts list Figure 2.2.1-Parts drawing, K60 stationary box rotator Table 2.2.1-Parts list for K60 stationary box rotator

Open the catalog to page 11

Commissioning the K60 stationary box rotator ATTENTION: Account must be taken of the correct direction of rotation of the generator when connecting it to the power supply. Where this is incorrect, the two phases should be switched around. To move the machine, first attach the transport hooks to the rotating frame. Set the lift truck forks so that the points engage under the transport hooks. Drive carefully and take account of the width and height of the machine. Slide the height adjuster to the correct box height, which must be 2 cm higher than the total box height. Fasten the box support...

Open the catalog to page 12

Parts list Figure 2.3.1-Parts drawing, K60-AKB stationary box rotator Table 2.3.1-Parts list for K60-AKB stationary box rotator

Open the catalog to page 13

General operation of K60-AKB stationary box rotator In this format the stationary box rotator is equipped with an ultrasonic sensor which can detect potatoes. The ultrasonic sensor detects the potatoes as they roll out of the box across the plate and the machine interrupts its tipping for a set interval. When no more potatoes are detected the machine will tip further and the cycle will begin again. The cycle will continue until the box rotator is fully tipped. It will then automatically tip back in the other direction, following a set interval. The empty box can then be replaced with a full...

Open the catalog to page 14

Commissioning the K60-AKB stationary box rotator J»\ Account must be taken of the correct direction of rotation of the generator when connecting it to Jr I \ the power supply. Where this is incorrect, the two phases should be switched around. 1. To move the machine, first attach the transport hooks to the rotating frame. Set the lift truck forks so that the points engage under the transport hooks. Drive carefully and take account of the width and height of the machine. 2. Slide the height adjuster to the correct box height, which must be 2 cm higher than the total box height. Fix the...

Open the catalog to page 15

Set the selector switch on the control cabinet to manual operation (2). Drive into the K60-AKB with a full box. As long as either the start/outward (8) key on the remote control or the raise (3) key on the control cabinet is depressed, the K60-AKB will tip the box until the end position is reached. If the stop/return (6) key on the remote control or the lower (4) key on the control cabinet is pressed, the stationary box rotator will return to its start position. Exchange the empty box for a full one, and repeat the previous actions. Where the K60-AKB is set up as a fixed installation it is...

Open the catalog to page 16All WIFO-ANEMA B.V. catalogs and technical brochures

-

v/d Grond

2 Pages

-

Lifting mast

1 Pages

-

Bulk loading bucket HO

1 Pages

-

Lifting mast HMZ

1 Pages

-

Weighing equipment

24 Pages

-

Three-point linkage side-shift

24 Pages

-

Loading bucket (fork mounted)

28 Pages

-

Bale clamp for rectangular bales

28 Pages

-

Manure fork/ZV

1 Pages

-

WV

1 Pages

-

Drainage machine DM 180

1 Pages

-

Forward tipping box rotator

2 Pages

-

Box Rotator

2 Pages