Catalog excerpts

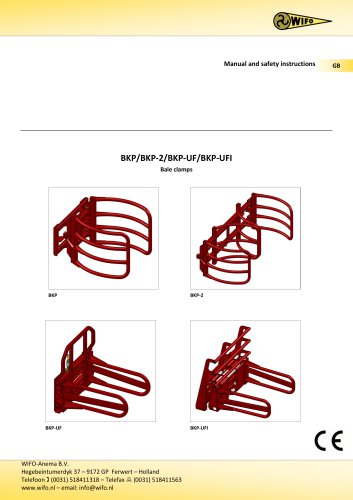

Manual and safety instructions WIFO-Anema B.V. Hegebeintumerdyk 37 – 9172 GP Ferwert – Holland Telefoon (0031) 518411318 – Telefax (0031) 518411563 www.wifo.nl – email: info@wi

Open the catalog to page 1

English Table of contents 1.

Open the catalog to page 3

The aim of this manual is to inform users about the commissioning, use and maintenance of their new WIFO sideshift. Also included in this manual are a number of safety instructions to create a safe working environment. At WIFO-Anema B.V. we aim to continuously improve our products. WIFO-Anema B.V. reserve the right to introduce any changes and improvements deemed necessary without prior notice. Please read the manual thoroughly and observe the safety procedures before putting the unit into operation. Contact your dealer for any further questions or concerns you may have. We trust that your...

Open the catalog to page 4

1.2 Safety precautions and warnings Please read this manual before you put the machine into operation for the first time, and observe the safety instructions at all times. The most important instructions are marked with a symbol. Any person in charge of the commencement of operation, the operation itself or the maintenance of the machine is urged to carefully read and observe the following instructions. 1.2.1 Safety precautions The following safety instructions apply to all types of WIFO sideshifts. No distinction is made with regard to the type of lifting vehicle used. Persons must not...

Open the catalog to page 5

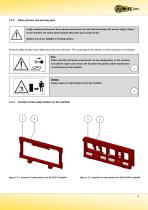

Saftey stickers and warning signs A safe working environment also requires personnel to be well-informed about the various safety stickers on the machine. Be aware of the hazards they warn you to look out for. Replace any loose, illegible or missing stickers. Several safety stickers have been put onto the machine. The meaning of the stickers on this machine is as follows: N.B.: Please read the instruction manual prior to any maintenance to the machine. Turn off the engine and remove the key from the ignition while maintenance is carried out on the machine! Danger: Always keep at a safe...

Open the catalog to page 7

Figure 1.2.3- Location of safety stickers for DSD-500 sideshift Figure 1.2.4- Location of safety stickers for DSD-600 sideshift WIFO sideshifts are suitable only for the transportation and side-shifting of pallets and boxes. The WIFO HS-2/HS-3 sideshifts are available for attachment on a FEM II or FEM III fork carriage of a forklift truck or lifting mast, provided that the total weight of the sideshift and the attached equipment does not weigh more than 2500kg for the HS-2 and 3500kg for the HS-3. The WIFO HSR-2/HSR-3 sideshifts are available with attachment parts on telescopic loaders,...

Open the catalog to page 8

Any person working with or on the machine must have read this manual. The machine is to be used for its intended purpose only. Included in the intended purpose are, among other things: 1. Work must be carried out in accordance with the directions and within the functional restrictions (e.g. maximum hydraulic working pressure) as outlined in the regulations. Use only sound and appropriate tools. 2. Electric/electronic equipment and accessories (e.g. cables) must be treated in accordance with the general accepted policy for using non-waterproof portable electric and electronic equipment, such...

Open the catalog to page 9

1 Sideshift-stroke is adjustable on the frame of the sideshift. The stroke can be adjusted as 500mm to the left or 500mm to the right, or 250mm to the left and right. Table 2.1.3-DSD sideshfits for tractors

Open the catalog to page 10

HS-2/HS-3 sideshift2.2.1 Parts list Number Table 2.2.1-Parts list for HS-2/HS-3 sideshift

Open the catalog to page 11

The following instructions apply to a FEM II or FEM III fork carriage of a forklift truck or mast. 1. 2. 3. 4. Remove the clamping strips from the sideshift. Remove the forks from the forklift truck or forklift mast and make sure the fork carrier is straight and clean. Place the sideshift onto the fork carrier of the forklift truck or forklift mast. Attach the clamping strips using two bolts M16x55. Secure these bolts tight! (140 Nm). Make sure there is some clearance between the clamping strips and the fork carriage so it moves freely. This is adjustable with the lateral movement of the...

Open the catalog to page 12

2.3.1 Parts list Number Table 2.3.1-Parts list for HSR-2/HSR-3 sideshift

Open the catalog to page 13

The following instructions apply to a FEM coupling: 1. Remove the clamping strips from the sideshift. 2. Remove the forks from the forklift truck or forklift mast and make sure the fork carrier is straight and clean. 3. Place the sideshift onto the fork carrier of the forklift truck or forklift mast. 4. Attach the clamping strips using two bolts M16x50. Secure these bolts tight! (140 Nm). 5. Connect the hydraulic hoses of de sideshift to the dual-action connection on the fork carrier. Make sure the hydraulic hoses are clean to prevent any debris from entering the hydraulics of the machine....

Open the catalog to page 14

DSD-500 sideshift2.4.1 Parts list Number Table 2.4.1-Parts list for DSD-500 sideshift

Open the catalog to page 15

WlFo2.5 DSD-600 sideshift2.5.1 Parts list Number Table 2.5.1-Parts list for DSD-600 sideshift

Open the catalog to page 16

The following instructions apply to a standard cat. II three-point hitch: Make sure that the lifting arms of the three-point hitch are on the same level. Attach the sideshift to the cat. II three-point hitch of the tractor. Use proper pins and locking clips. Place the sideshift as horizontal as possible by adjusting the top link. The lateral backlash of the sidehift in the three-point hitch should be kept to a minimum. Adjust this with the stabilizers of the three-point hitch Connect the hydraulic hoses of de sideshift to the dual-action connection on the tractor. Make sure the hydraulic...

Open the catalog to page 17

Table 2.6.1-Spare parts WIFO sideshifts

Open the catalog to page 18

Various bearings for HS-2/HS-3 sideshifts Figure 2.6.1-Slide bearing above CCD for HS-2 Figure 2.6.2-Slide bearing below CCD for HS-2 Figure 2.6.3- Slide bearing above CCD for HS-3 Figure 2.6.4- Slide bearing below CCD for HS-3

Open the catalog to page 19

Figure 2.6.5-Slide bearing above MTT for HS-2 Figure 2.6.6-Slide bearing below MTT for HS-2 Figure 2.6.7- Slide bearing above MTT for HS-3 Figure 2.6.8-Slide bearing below MTT for HS-3

Open the catalog to page 20All WIFO-ANEMA B.V. catalogs and technical brochures

-

v/d Grond

2 Pages

-

Lifting mast

1 Pages

-

Bulk loading bucket HO

1 Pages

-

Lifting mast HMZ

1 Pages

-

Stationary box rotator

24 Pages

-

Weighing equipment

24 Pages

-

Loading bucket (fork mounted)

28 Pages

-

Bale clamp for rectangular bales

28 Pages

-

Manure fork/ZV

1 Pages

-

WV

1 Pages

-

Drainage machine DM 180

1 Pages

-

Forward tipping box rotator

2 Pages

-

Box Rotator

2 Pages