Excertos do catálogo

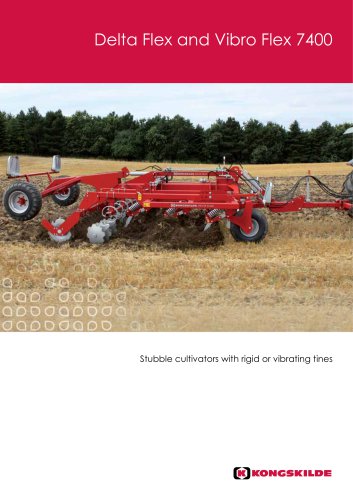

Stubble cultivators with rigid or vibrating tines

Abrir o catálogo na página 1

What is obtained by correct stubble cultivation? Incorporation of straw and field residues • Quick decomposition due to the mixing of both straw and plant residues with the soil • Utilizing the moisture in the soil just after harvest • Establish an optimal climate for microbes to work in Establishment of a stale seedbed for germination of weed seeds • Shallow cultivation directly after harvest will encourage lost seeds and weed seeds to germinate • Seedbed preparation for establishing intermediate crops such as mustard, oil radish etc. • No slug nutrition Preparation of a seedbed in mulch...

Abrir o catálogo na página 2

Common platform offers flexibility Main advantages: • Reliable heavy duty construction • Blockage-free operation through large frame clearance and tine spacing • Safe access for wearing part replacement when wings folded to vertical • Wing pressure system allows machine to follow field contours • Simple adjustment of the working depth by pin/hole system • Changing the working depth has no effect on the levelling system settings after basic adjustment • Transport wheels at the rear for safe road transport • Reduced soil compaction on headlands through wide profile transport tyres • Modular...

Abrir o catálogo na página 3

Delta Flex Rigid tine stubble cultivator Main advantages: • Rigid tines ensure an even working depth • Working depths from 6 - 25 cm in one pass • Fitted with wing shares a full cut across the entire working width is achieved • Without wing shares fitted, deeper loosening down to 25 cm is possible in one pass • Optimal mixing of straw and residues is the result of the special curved stems, which encourage a rolling soil action • Release force of 400 kg on the tip of the point • High release clearance of 25 cm • Easy conversion from shearbolt to non-stop version Benefit for the user: • Delta...

Abrir o catálogo na página 4

Vibrating tine stubble cultivator Main advantages: • The constantly-vibrating Vibro Flex tines leave an open soil structure • An extra crumbling effect is obtained, as the soil breaks up in the natural fracture lines • 4 rows of tines for a more intensive mixing of field residues with soil in one pass • Heavy duty VFM-spring with built-in backwards and sideways overload protection • Constant working depth as share point always operates directly under the tine flex point • Working depths from 6 – 15 cm in one pass and up to 25 cm in the following pass • Wide range of heavy duty high quality...

Abrir o catálogo na página 5

Levellers Intensive levelling of the soil after the cultivator tine section is the premium criterion for quality reconsolidation. For the Delta Flex and Vibro Flex 7400 ranges Kongskilde offers 2 options for levelling. Disc leveller • Constant and blockage-free rotation. • One-step depth adjustment together with the cultivation depth • Frame connection via Kongskilde VTH spring, acting as suspension • Further mixing of plant residues with soil for quicker decomposition. • Mounted in sections, with 2 0460mm notched discs on each section. • Spindle depth adjustment Hockey stick leveller •...

Abrir o catálogo na página 6

Crumble roller • Well-known Ø550 mm diameter crumble roller • Good choice in most soil types, with special advantage of constant rotation. • Cost-effective alternative to Max Pack and Vibro Pack rollers; in many cases a substantial packing and crumbling effect is achieved. Shares • Wide range of genuine high quality shares for Delta Flex and Vibro Flex 7400 to suit different applications. • Made in hardened boron steel for a long lifetime. Front disc section (Vibro Flex 7400) To cut and separate plant residues (maize, oil seed rape etc) an independent disc section can be used in front of...

Abrir o catálogo na página 7

Work Width Transport width Cat. Weight incl. crumble roller Front wheels Tine spacing Power requirements hp Subject to be changed without notice. 101001585 EXP/GB/Stubble cultivation/BRO/0412 mail@kongskilde.com www.kongskilde.com (k) kongskii.de Kongskilde Industries A/S Tel. +45 33 68 35 65 adding value to the green world

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos KONGSKILDE Industries A/S

-

VIBRO SEEDER 6000

4 Páginas

-

1-rotor rakes

8 Páginas

-

Rotavator

6 Páginas

-

Kongskilde Ploughs

28 Páginas

-

Complete diet mixers

32 Páginas

-

NS 1500 - 1900

2 Páginas

-

Vibro Compact

4 Páginas

-

Tedders

8 Páginas

-

Front Terra C

2 Páginas

-

Semi-mounted reversible ploughs

8 Páginas

-

SB4000/SB5200

4 Páginas

-

Vibro Crop 2017

4 Páginas

-

Rotary rakes with 2 rotors

8 Páginas

-

Clean cut 2021

20 Páginas

-

Trailed forage harvesters 2021

12 Páginas

-

VIBRO TILL 2900

8 Páginas

-

Delta Flex and Vibro Flex 7400

8 Páginas

-

COMBI JET

8 Páginas

-

COMBISEED HT3000S-HT4000S

4 Páginas

-

FLEXI DRILL

4 Páginas

-

MULTI JET

8 Páginas

-

KONGSKILDE FRONT TERRA DISC

2 Páginas

-

KONGSKILDE TERRA-D

2 Páginas

-

DELTA FLEX

8 Páginas

-

KONGSKILDE DELTA SHEAR BOLT VERSION

4 Páginas

-

VIBRO FLEX 2000/4000/4200/4300

6 Páginas

-

VIBRO FLEX FRONT MOUNTED

6 Páginas

-

VIBRO TILL 2900 SF

8 Páginas

-

VIBRO TILL 8200 SF

12 Páginas

-

BETTER FUEL EFFICIENCY

2 Páginas

-

ÖVERUM CT-F

2 Páginas

-

XLD PLOUGH BODY

5 Páginas

-

KONGSKILDE MS-MT

2 Páginas

-

VIBRO CROP VCR

2 Páginas

-

KDC 8000

4 Páginas

-

ASPIRATOR PRE-CLEANERS - KF

8 Páginas

-

FAN GUARD

2 Páginas

-

PNEUMATIC GRAIN CONVEYING

16 Páginas

-

R+ 1610

8 Páginas

-

R+ 2 ROTORS

8 Páginas

-

Rear mounted drum mower - CM 305

2 Páginas

Catálogos arquivados

-

Trailed forage harvesters 2016

12 Páginas

-

Clean cut 2016

20 Páginas